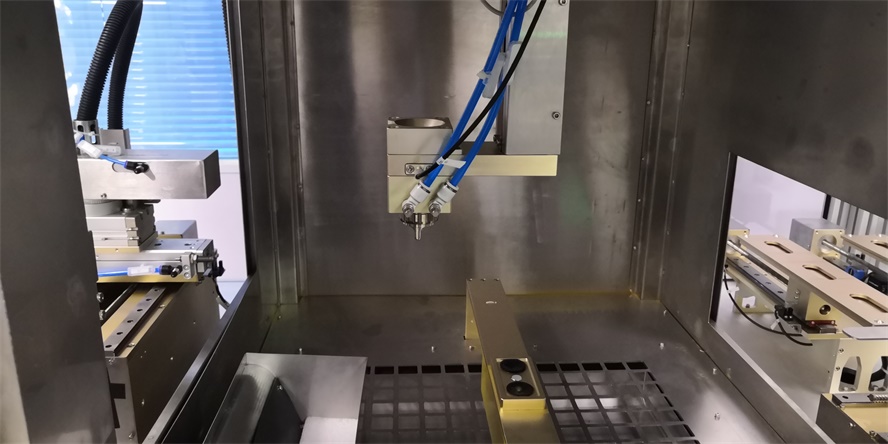

With the development of Industry 4.0 and product innovation, the Internet of Things has revolutionized the technological revolution and industrial transformation of traditional industries. Traditional manual spray has many drawbacks in energy conservation, environmental protection, precision and efficiency. It is necessary to develop a device suitable for coating with a small amount of paint and a large variety of types, which can realize automatic loading of substrate, automatic paint loading, controllable film thickness and precision, and meet the requirements of paint film preparation process required for paint test. BEVS has developed the first small mobile Intelligent Panel Coating Station in the industry that integrates intelligent instruments, mechanical actions, automatic control systems and test materials.

Automatic material loading and unloading and rapid spraying greatly improve the reproducibility and efficiency of the film application, and it obtains a coating having uniform physical, appearance and chemical properties. It eliminates various instabilities caused by human factors such as speed, pressure and direction during film application, and provides high-precision test results for testing the rheological properties, wear resistance and hiding power of tested materials. The workstation combines technologies in the fields of automation, paint and chemicals, control, computers and information. It is the combination and application of intelligent manufacturing and quality inspection. The working principle of the workstation is to control the PLC through a special unit, the PLC controls the peripheral equipment, and the PLC communicates with each module by the communication protocol to realize the automatic film application. It is suitable for a wide variety of paints and needs a little sample. The system can store test panels of different specifications at a time (more than 20 pieces), different kinds of paints (6 types), thickness repeatability error can be controlled in the range of 3um by precise spraying via automatic mechanism. The system responds to the China Industry 4.0 and energy conservation and environmental protection call, it is based on high-precision, high-efficiency automatic mechanism, workstation platform and intelligent control system. It perfectly applied to a small number of automatic sample preparation laboratories for paints and chemicals, reducing waste gas and water, improving the spraying environment. It also realizes intelligent automatic high-efficiency film application by implementing two-way verification communication through the encryption protocol of the central control, automatic mechanism and peripheral institutions.

Features

*Real-time data encrypted transmission

*Fully automatic

*Free combination of instruments and equipment

*Remote command anytime, anywhere

*Get data, analysis, and results reporting anytime, anywhere

*Sharing with intelligent, automated workshop production

*Shorten research and development, testing cycle

*High efficiency and greatly reduced R&D costs

*Data saving and output

*Compatible with many different paints and realizing rapid automatic film application

Application

Suitable for paints, inks, packaging, printing, daily chemicals, universities, research institutes, testing institutions, etc.

Main functions

*Fully-automatic control of spray gun axis-movement

*Preset multiple common viscosity spray modes, input the required coating thickness value, the system automatically spray

*Customize spray mode: input spray moving speed, gun distance, atomization pressure, paint pressure, spray cycles and other parameters, the system automatically sprays according to the set parameter, custom spray mode can be saved for next time

*The interface displays the current parameters in real time, such as the current coating thickness, the run spray cycles, remaining spray cycles, the estimated final film thickness, and the estimated remaining time

*Quick replacement of 6 kinds different paints

*Fully enclosed to avoid contamination of the external environment during spraying

*Real-time monitoring of humidity, temperature and VOC in the internal environment

* The exhaust gas is discharged by a pipe, the waste water is stored in a special tray

System technical parameters

1) Technical parameters

Standard test panel size: Length 150mm, width 70mm wide (replaceable fixtures compatible with different panel size)

Paint storage: 6 types

Unsprayed test panel storage: 20 pieces

Sprayed test panel storage: 6 pieces

Single maximum paint capacity: 30ml

2) Spray Parameters

Applicable paint type: water-based and solvent-based

Applicable paint viscosity range: 1-20000 cps

Moving speed: X-axis 0-100 mm/s; Y-axis 1-100 mm/s

Stroke length: X-axis 210 mm; Y-axis 210 mm

Gun distance: 150-210 mm

Atomization air pressure: 0-0.7 Mpa

System pressure: 0-0.7 Mpa

Spraying area: max. 210*210 mm

3) System parameters

Continuous spray speed: 30s per panel

Continuous working time: 6*12h

4) Feeding device

Automatic load and unload

5) Electricity and compressed air requirements

Voltage: 220V/50Hz

Power: 1.5 KW

Air pressure: 0.6 Mpa (oil-water free)

6) Operating environment

Temperature: 0-45 ° C

Humidity: 20-80% RH (no condensation)

Vibration: <4.9m2/s

7) Size and weight

Workstation size: 1900x1300x2000mm (length x width x height)

Workstation weight: net weight 450kg