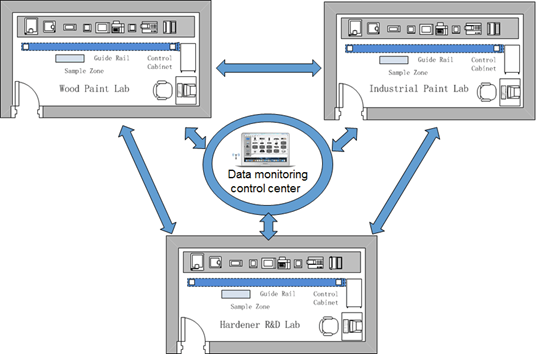

BEVS can customize professional intelligent R&D and testing solutions according to different R&D experiment requirements to realize intelligent automatic experiment and testing of raw materials, coatings, inks and etc.

Advantages:

*Real-time data encrypted transmission

*Automatically complete the task

*Remote command system

*Get data, analysis, and results reports anytime, anywhere

*Shared with intelligent, automated workshop production

* Shorten R & D and experimental cycle

* High efficiency and greatly reduced R&D costs

*Compatible to test a variety of materials

*Fast automatic loading and unloading

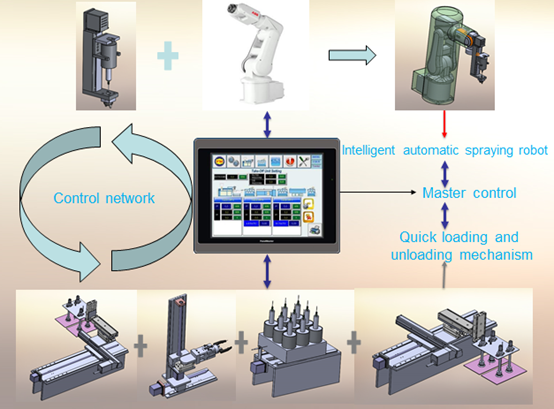

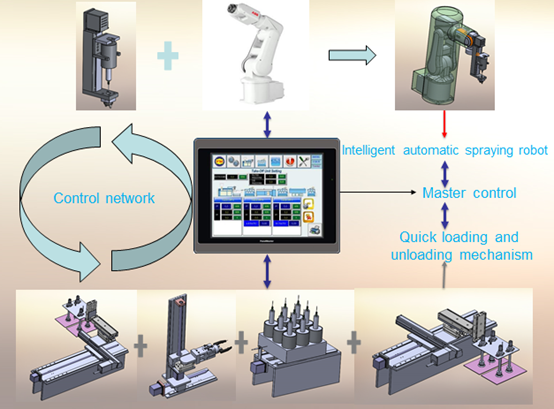

1) Intelligent integrated R&D working station

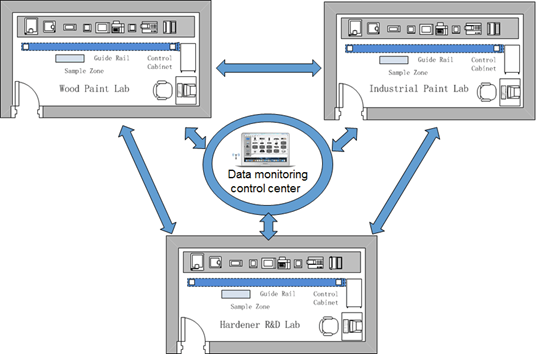

2) Multiple labs linked for intelligent R&D

Example:

Intelligent Panel Coating Station(click the video below for more info)

Introduction:

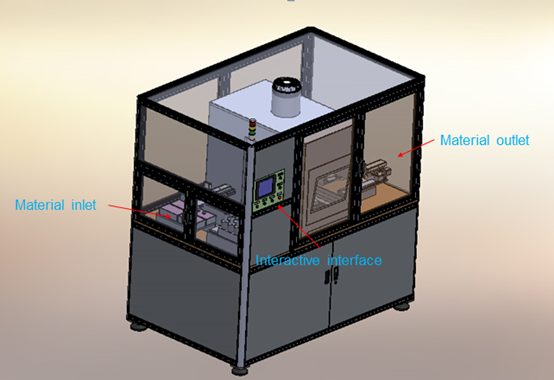

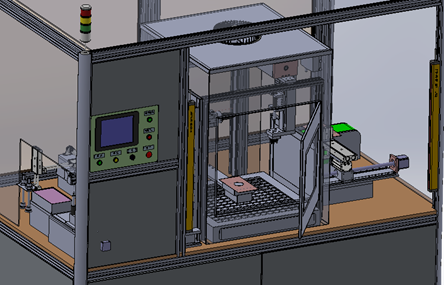

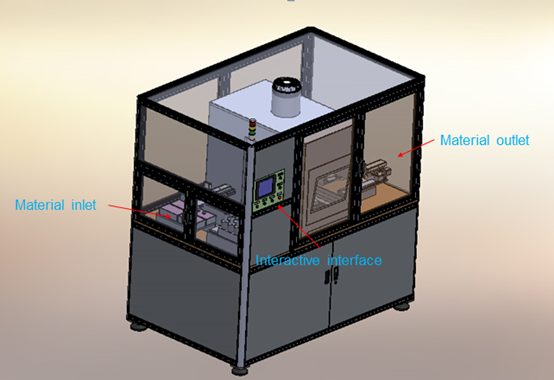

BEVS 3226 Intelligent Panel Coating Station is a smart small mobile workstation that integrates intelligent instruments, mechanical actions, automatic control systems and test materials.

The station automatically completes the loading and unloading, realizes the rapid panel coated, greatly improves the reproducibility and efficiency of the coating, and obtains the uniform film which has the same physical properties, appearance and chemical properties. All kinds of instability caused by the factors such as velocity, pressure and direction in the application process are eliminated.

Features:

-Real-time data encrypted transmission

-Free combination of instruments and equipment

-Remote command anytime, anywhere

-Get data, analysis, and results reporting anytime, anywhere

-Sharing with intelligent, automated workshop production

-Shorten research and development, testing cycle

-High efficiency and greatly reduced R&D costs

-Data saving and output

-Compatible with many different coatings and realize rapid automatic panel coated

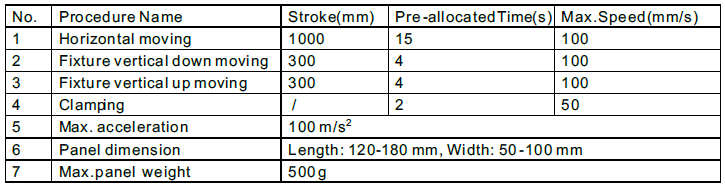

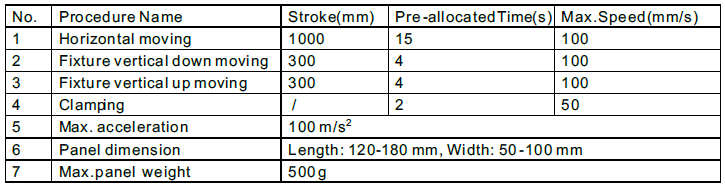

Technical Parameters for Each Process:

Spray Parameters:

-Applicable paint type: water-based and solvent-based

-Applicable paint viscosity range: 1-20000 cps

-Moving speed: X-axis 25-250 mm/s; Y-axis 25-250 mm/s

-Stroke length: X-axis 220 mm; Y-axis 220 mm

-Gun distance: 210 mm

-Atomization air pressure: 0.3-0.7 Mpa

-System pressure: 0.4-0.7 Mpa

-Spraying area: max. 100 × 180 mm

-Spray gun type: no-clean automatic spray gun

System Parameters:

-Continuous spray speed: 60 s/pcs

-Continuous working time: 7 x 12 h

-Maximum storage paints: 10 pcs

-Maximum storage of standard substrate: 20 pcs

-Maximum storage coated panel: 20 pcs

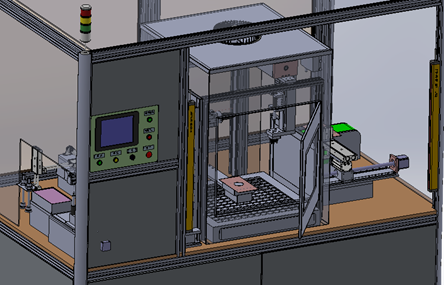

Main Structural Module:

-Moving mechanism: spray gun X, Y two-axis motion mechanism

-Test panel coding, paint syringe code-reading device

-Spray gun: A non-standard R&D spray system that can quickly change the type of paint

-Compressed air supply and pneumatic control system

-Panel fixing, loading, unloading and storage mechanism; paint syringe fixing, loading, unloading and storage mechanism

-Positioning connection device in workstations

-Automatic change mechanism of the paint syringe

-Spraying environment detection system: Real-time detection of humidity, temperature and VOC concentration in the internal working environment

-Waste discharge module: exhaust gas and sewage discharge device

-Electrical control system

Functions:

-Full-automatic control of double-axis (X, Y) movement

-Preset multiple common viscosity spray mode, input the required coating thickness value, the system automatically spray

-Custom spray mode: input spray moving speed, gun distance, atomization pressure, paint pressure, spray cycles and other parameters, the system automatically sprays according to the set parameters, custom spray mode can be -saved for next time

-The interface displays the current parameters in real time, such as the current coating thickness, the run spray cycles, remaining spray cycles, the estimated final film thickness, and the estimated remaining time

-Quick replacement of 10 kinds different paints

-Fully enclosed to avoid contamination of the external environment during spraying

-Real-time monitoring of humidity, temperature and VOC in the internal environment

-The waste is discharged by means of gas and sewage

Order Information:

BEVS 3226 Intelligent Panel Coating Station (custom available upon request)