Produtos

- Dispersão

- Densidade / Moagem

- Viscosidade

- Aplicação de Filme

- Mini aplicador de filme automático

- Aplicador Automático de Filme

- Aplicador de face única

- Aplicador frente e verso

- Aplicador de quatro lados

- Aplicador de quatro lados com reservatório

- Aplicador de cubo

- Aplicador ajustável

- Aplicador de flacidez

- Aplicador de nivelamento

- Extensor Expiral

- Alça de barra

- Gráfico de poder oculto

- Aplicador Ajustável Digital

- Kit de aplicação de filme

- Pulverizador de painel automático

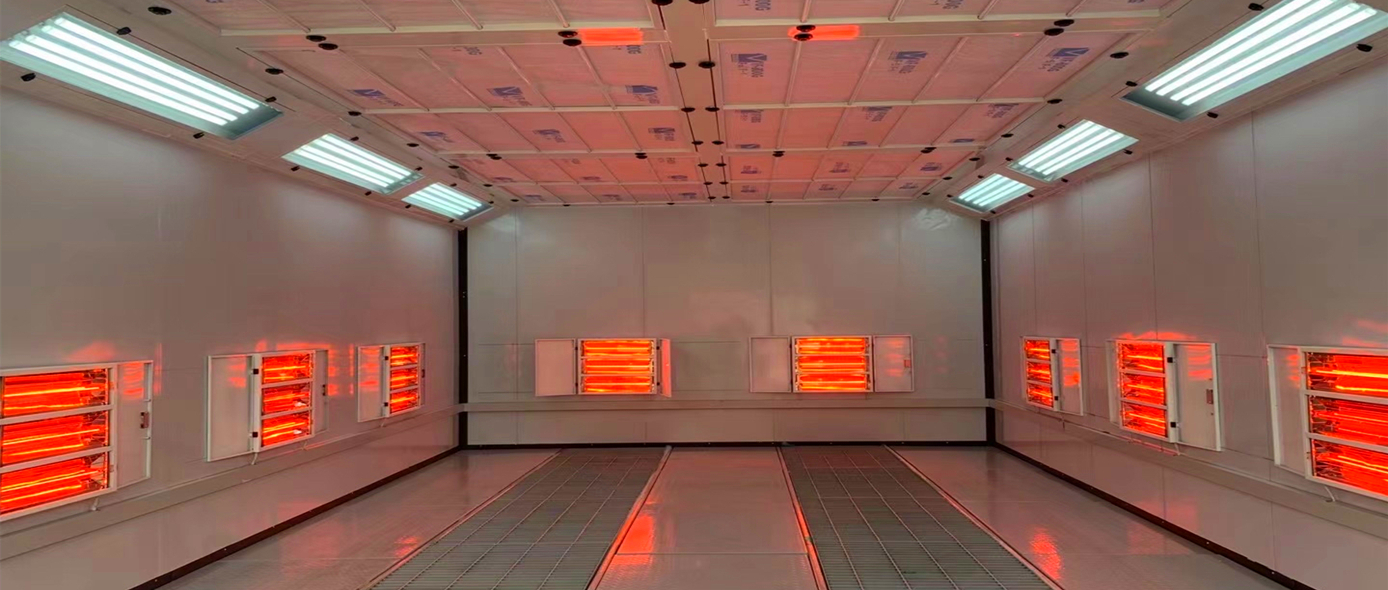

- Tempo de secagem

- Espessura

- Temperatura

- Cor / brilho

- Adesão

- Dureza

- Deformação

- Abrasão, Esfrega / Lavabilidade