Some customers responded that when using manual pencil hardness tester to do coating hardness test, the same test panel and instrument, different people go to operate in accordance with the specified test method, often produce results with large differences. For this reason, BEVS laboratory used a set of comparative test data to answer the customer's question.

What materials can the pencil hardness test be used for?

Pencil hardness test focuses on characterizing the surface hardness of materials, reflecting the coating's ability to resist indentation, scratching and scuffing, and is widely used in the fields of coatings, inks, plastics, paper and so on.

As a simple and practical coating hardness test method, the pencil hardness tester is usually applied to thin coatings (<0.3mm) with relatively low hardness, such as wood coatings, wall coatings, floor coatings, and so on.

Why is it that when using a manual pencil hardness tester, the

more prone to error conditions?

Prepare:

1. Pencils: Prepare a set of pencils of the same brand and from the same batch, sharpen them with a special pencil sharpener to a standardized cylindrical shape, and sharpen the tip of the pencil horizontally. Repeat this step before each use of the pencils.

2.Test plate: Prepare the same batch of test plates with the same coating thickness to ensure that the surface is clean and free of contamination.

3. Instruments: Manual pencil hardness tester, electric pencil hardness tester.

Effects of different testers

Test conditions: A test plate with a coating thickness of 200 μm, for example, was tested by different testers using 2 test methods, in which the electric pencil hardness tester was set at a speed of 1. 0 mm/s, with a running time of 10 s; the manual pencil hardness tester was selected to be fast-advancing.

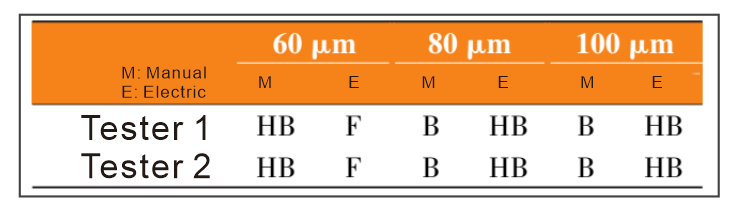

Table 1: Coating hardness using 2 test methods by different testers

As can be seen from Table 1, experienced testers were consistent in their determination of the results.

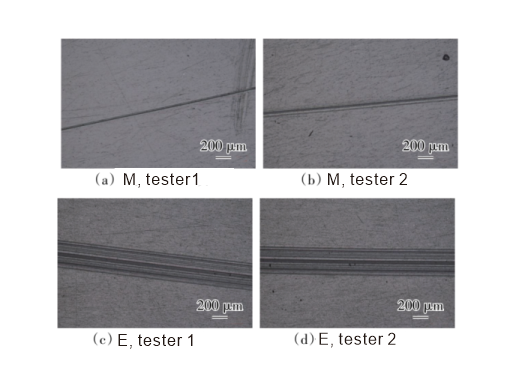

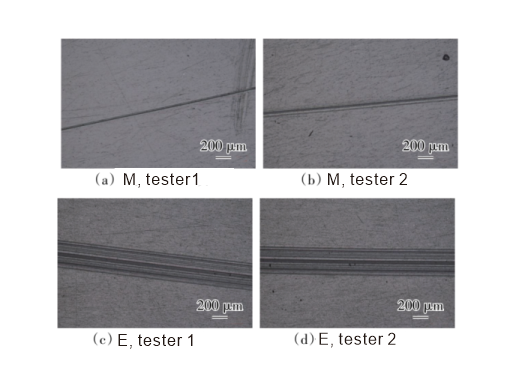

Figure 1: Test plate with 200 μm coating thickness

Microscopic results of pencil hardness (H) at different testers

As can be seen from Fig. 1, the depth of scratches on the coating is different for different testers when testing with a manual pencil hardness tester, and the intuition on the microscope image is that the scratches are different in color, width, and morphology. This is because each tester has his own customary methods, the adjustment and judgment of the level of the instrument, and the grasp of the speed vary from person to person, which will cause the difference in the results.。

Impact of manual vs. electric

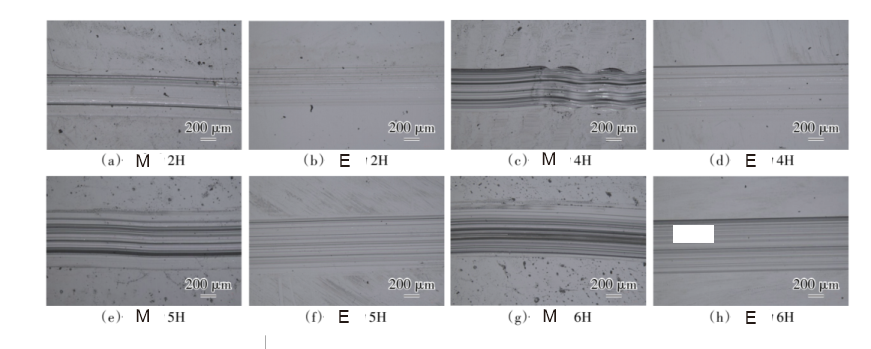

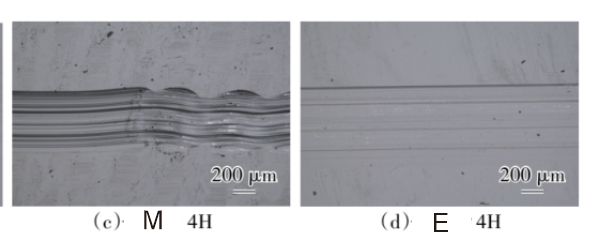

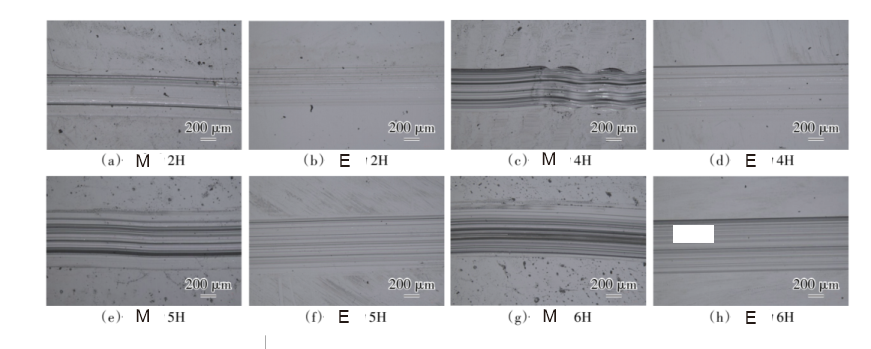

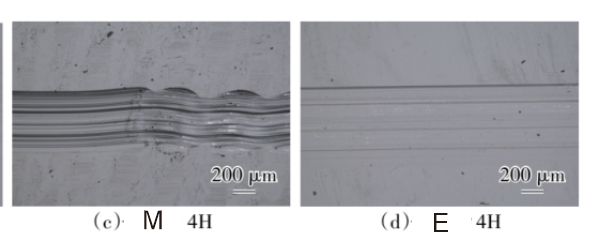

Test conditions: Take a test plate with a coating thickness of 200 μm as an example, use 2H, 4H, 5H and 6H hardness pencils to scratch on the coating surface by manual and electric pencil hardness testers at a speed of about 1.0 mm/s, respectively, and analyze the scratches by magnifying them 50 times with an inverted metallurgical microscope, and the results are shown in Fig. 2.

Figure 2: Microscopic observation results

As can be seen from Figure 2, the scratch lines of the manual pencil hardness tester are incoherent, uneven, not straight, and even faults, 4H is particularly obvious, while the electric pencil hardness program scratch lines are very smooth and even.

In the same thickness of the coating test, manual pencil hardness tester in the process of advancing is difficult to avoid artificial more pressure, so early defects. At the same time, the manual pencil hardness tester can not guarantee uniform speed, the human factor has a greater impact, making the scratches are not smooth and uneven.

Analysis of microscopic results

In practice, the range of differences between the same levels of pencil hardness is large and does not reflect the smaller differences in hardness between coated films, i.e. the same pencil hardness of a coated film may have a significant difference in actual softness.

According to GB/T6739-2006/ ISO 15184, scratching the surface of the paint film with a pencil lead will cause one or two of the following defective conditions on the surface of the paint film: plastic deformation, cohesive damage (abrasion or scratching).

As can be seen from Fig. 2, the reproducibility of the manual pencil hardness schedule scratches is poor. With the help of microscopy results, we can further analyze the scratch pattern, length, width and other parameters of the electric pencil hardness tester to assess the difference in abrasion resistance of materials with the same pencil hardness.

The results of the coating hardness test are mainly influenced by the preparation of the test plate, the performance of the test setup, the coating, the test speed, the horizontal positioning, and the applied load.

Manual pencil hardness tester in the test process due to human resistance factors, manual exertion of force, speed is inconsistent, resulting in unstable test results repeatability, need to rely on the tester's excellent technology.

Electric pencil hardness tester can better control the influencing factors, reduce the error, improve the accuracy of the results, so the test results are highly repeatable.