Pertence à categoria: Seminar

Data de lançamento: 2024-03-29

Taxa de clique: 5153

A editora: Xiaohei

Coleção:

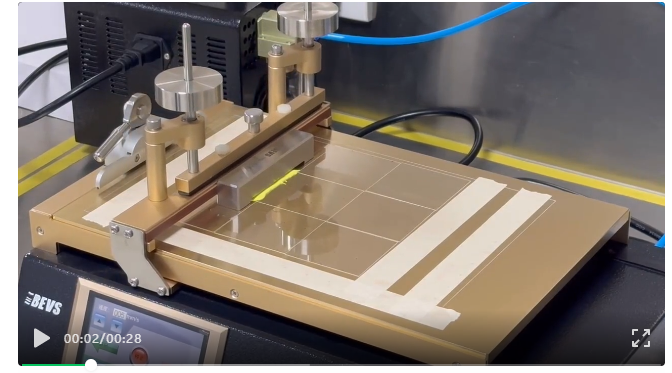

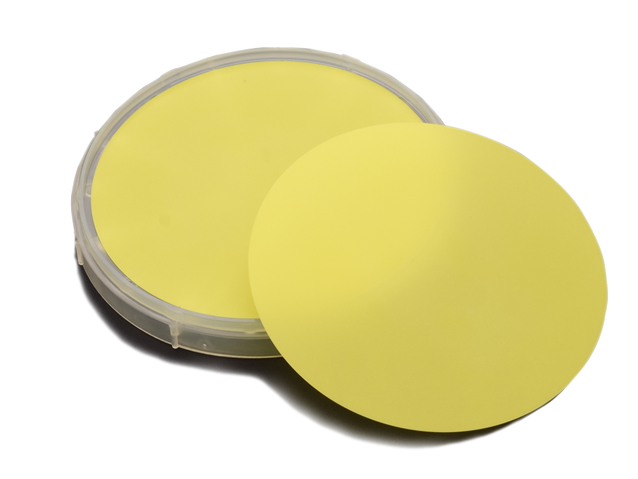

Recently, BEVS automatic film applicator has successfully solved another application problem for users: drawdown low leveling fluorescent paste on small area sapphire chips.

Firstly, let me introduce the application significance of coating fluorescent paste on sapphire chips. The application of coating fluorescent paste on sapphire chips is mainly to form a uniform and precise fluorescent coating on the surface of sapphire chips, and to prepare a fluorescent thin film with excellent luminescent performance through high-temperature drying.

Fluorescent film is an oxide thin film that can emit fluorescence. Due to its excellent fluorescence properties, it can be widely used in fields such as biomedical science, materials science, and environmental monitoring. The following is an introduction to several common applications:

01 Laser lighting field

01 Laser lighting field

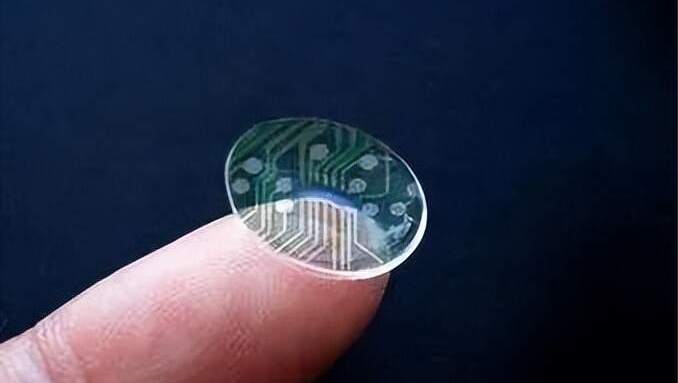

In the field of laser lighting, composite fluorescent films have the advantages of high thermal conductivity, high refractive index, controllable size and shape. They can withstand long-term irradiation by mainstream high-power LEDs or lasers, improve the service life of high-power LED or laser lighting equipment, meet special lighting field applications, and are suitable for processing and packaging of existing high-power LED or laser lighting equipment, helping to reduce the cost of high-power LED or laser lighting equipment.

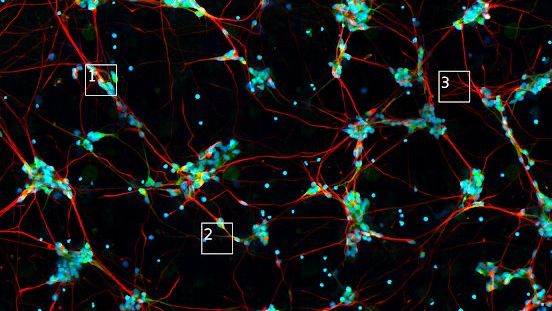

In the field of biomedicine, fluorescent membranes are widely used in cell imaging, drug delivery, cancer treatment, and other fields. Taking cell imaging as an example, by attaching fluorescent membranes as markers to the cell membrane, scientists can observe the movement trajectory and internal structure of cells, and also determine whether cells are growing normally.

In addition, in terms of med transport, scientists can monitor the transport process and targeting effect in vivo by placing fluorescent membranes inside the drug. In cancer treatment, fluorescent membranes can be used as fluorescent probes to track the location and quantity of cancer cells, assisting doctors in developing better treatment plans.

In the field of materials science, fluorescent films can be used for the preparation of materials, sensors, and electronic devices. Taking material preparation as an example, fluorescent films can be used to react and generate materials with different colors and properties. In terms of sensors, fluorescent films can be used to make various sensors, such as temperature sensors, optical sensors, etc.

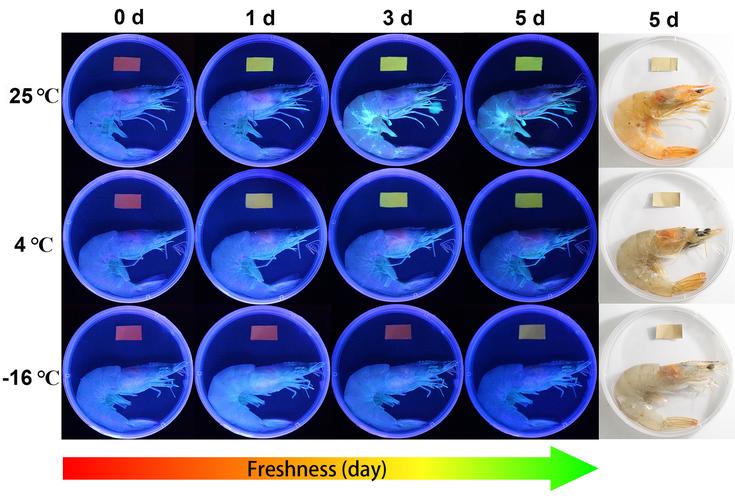

04 Environmental monitoring field

In the field of environmental monitoring, fluorescent membranes can be used to detect environmental pollutants such as water and atmosphere. Taking the detection of pollutants in water as an example, by fixing certain detection elements on a fluorescent membrane, chemical reactions will occur when pollutants enter the membrane and release fluorescence signals, thereby achieving the detection and judgment of pollutants in water.

Of course, with the continuous development of technology and preparation methods, research on fluorescent films will provide more possibilities and be more widely applied in industrial fields.

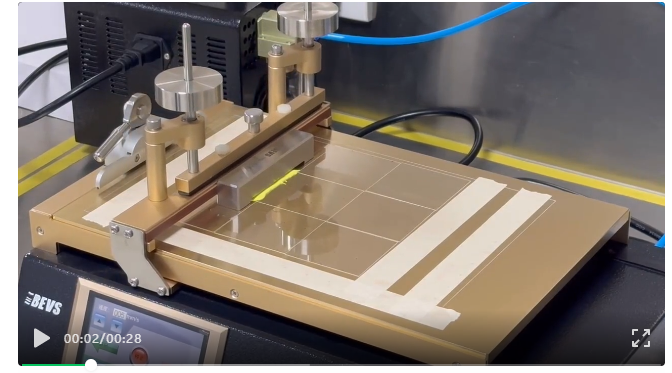

In this application case, there are actually several operational difficulties. Firstly, the substrate is a 60 × 50mm ultra-thin square sheet, which is prone to substrate displacement and coating adhesion issues when applied in small areas; Secondly, the sample prepared by the customer is a low leveling fluorescent paste. For this type of sample, attention should be paid to setting a lower speed to ensure that the sample is evenly distributed during the coating process and avoid affecting the coating effect.

Based on the characteristics of the samples, BEVS have prepared a auto applicator with a vacuum platform. The starting point is located on one side of the sapphire sheet, and the fluorescent slurry is evenly squeezed at the front end of the preparation device. The speed is set to 5mm/s.

Drawdown:

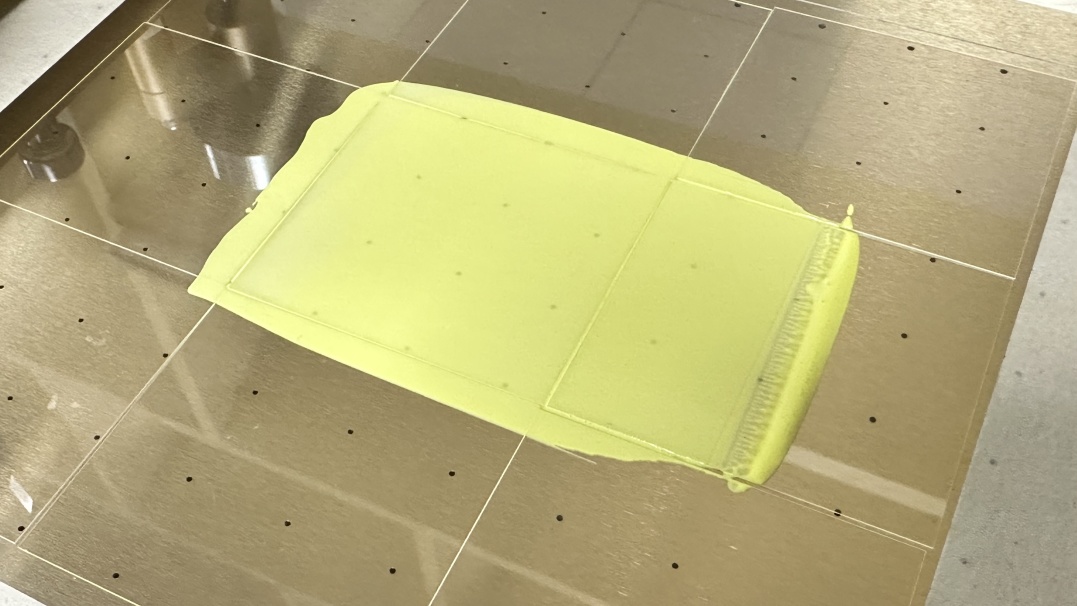

Final result:

The thickness and color of the fluorescent paste coating are uniform and consistent, and the film forming effect is good after drying, which meets the customer's expectations.

01 Laser lighting field

01 Laser lighting field