Coating cracking not only affects the appearance of the product, but also has an impact on its corrosion resistance and service life. Cupping test is an essential test item for those coatings that need to be post-moulded in the coil coating industry and the can making industry, such as coiled steel coatings and canning paints. Cupping Tester is mainly to detect the steel plate and iron plate surface paint film cracking resistance test, can help users quickly and accurately automatically determine the metal surface coating and related products from the substrate to peel off the tensile strength.

Automatic cupping tester and traditional manual measurement method to measure the cupping value of different test boards are compared to find out the differences, advantages and disadvantages of the 2 measurement methods, and to analyse the feasibility and practicability of measuring cupping by the 2 methods, in terms of operation flexibility, stability, thickness of the test boards, speed of cupping, judgement when observing the cupping crack, repeatability of the measurement results, poor reproducibility, and so on.

Manual cupping Test: The traditional manual operation steps are carried out in accordance with GB/T 9753.

Automatic cupping Test: Open the instrument, calibrate the ‘0’ position. Replace the calibration panel with the test panel (note that the paint film side should face up), and fix the test panel automatically with the fixture; then choose the constant speed of 0.2mm/s to carry out the cupping until it reaches the depth of the specified settings.

1 Effect of different cupping depths on cupping results.

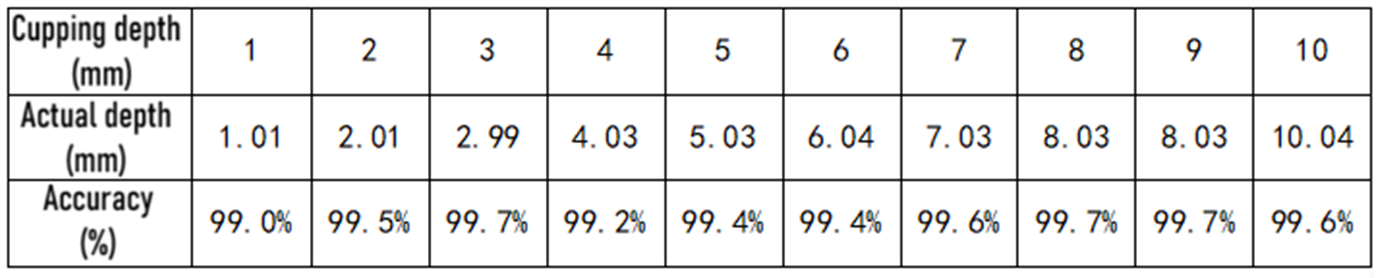

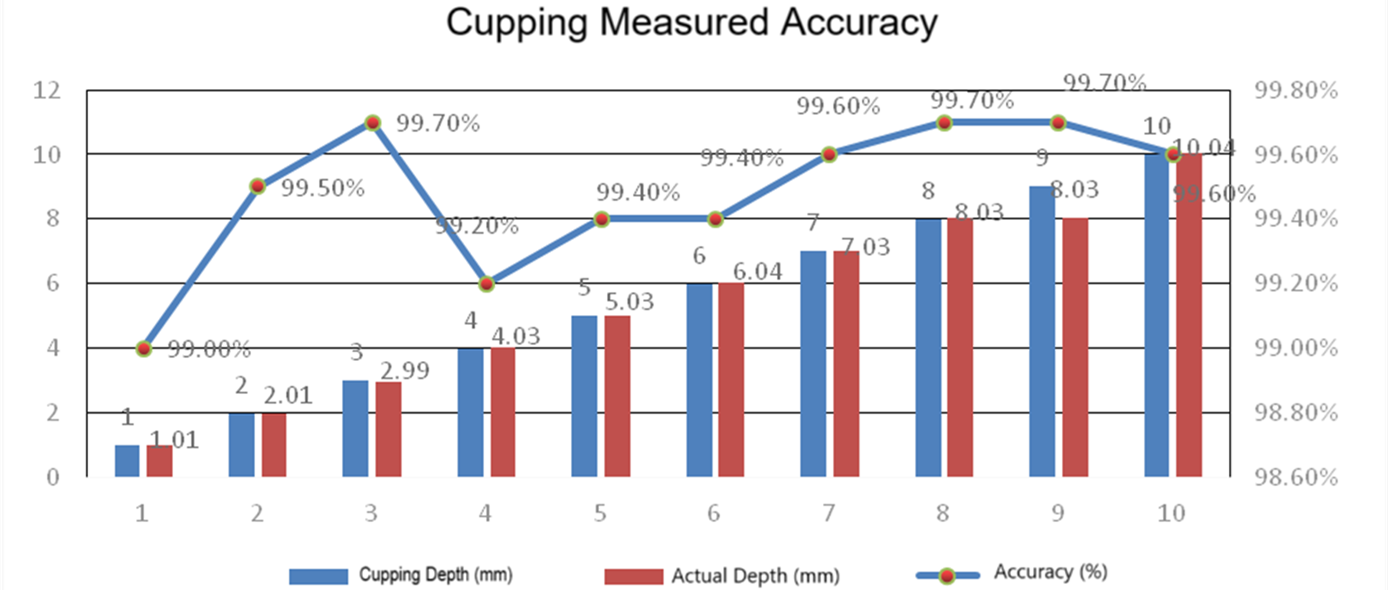

Replace the calibration panel with the test panel (note that the paint film side should face up), and use a fixture to automatically fix the test panel; then select a constant speed of 0.2mm/s for cupping until the specified depth is reached (as shown in Table 1).

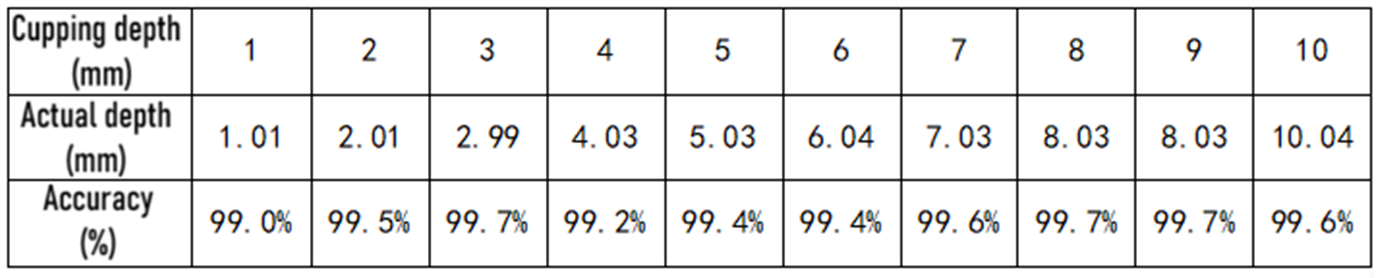

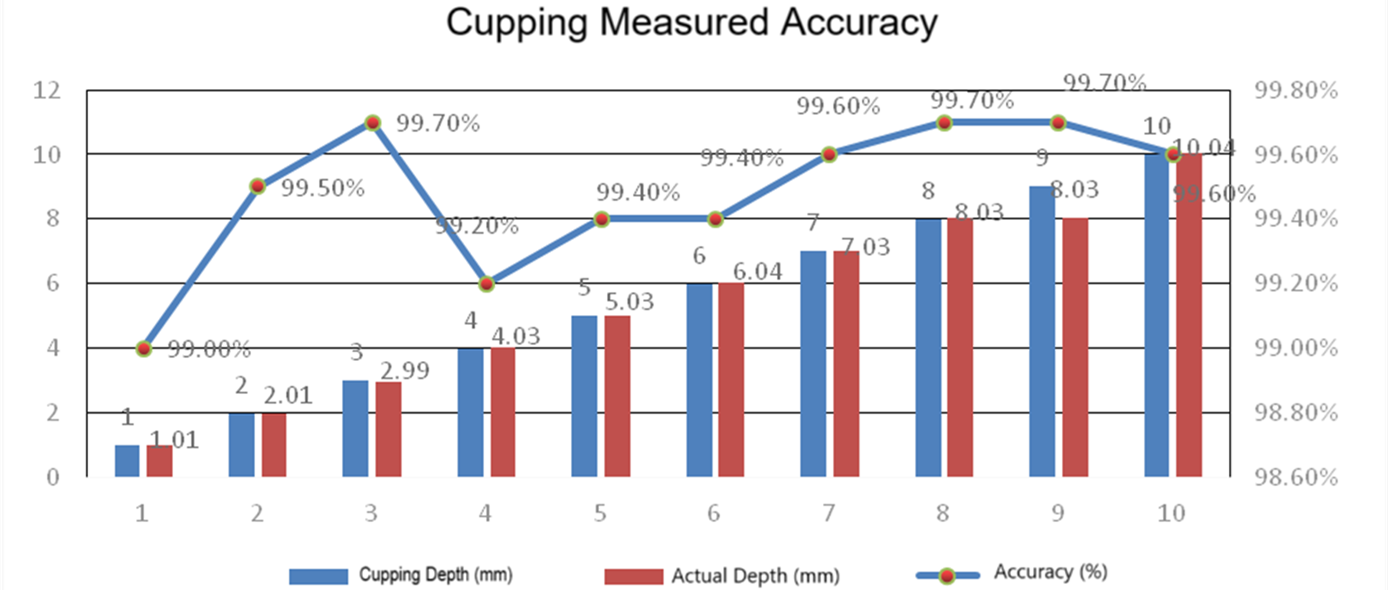

Table 1: Using a 1mm single-sided coated iron panel, cupping tests of different depths were performed at a speed of V=0.2mm/s

Conclusion:The cupping test of different depths was performed at a speed of 0.2 mm/s. From the test data and the curve chart, it can be seen that the test result accuracy is above 99%. After multiple tests, it is concluded that the test method is very accurate.

2 Effect of different test panel thickness and cupping speed on cupping results

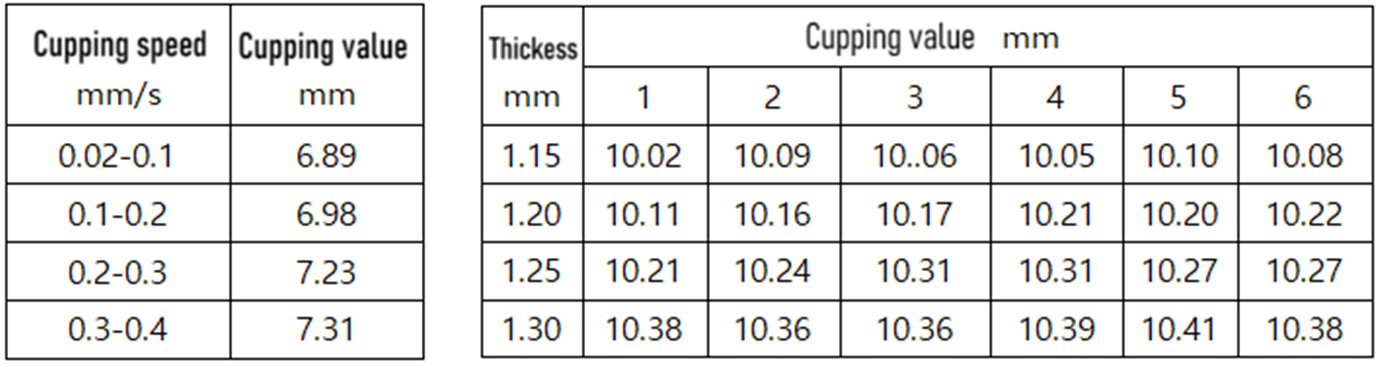

The cupping test was conducted using an Automatic Cupping Tester with different test panels of different thicknesses and different cupping speeds, and the main factors affecting the accuracy of the cupping value were found: test panel thickness and cupping speed, as shown in Table 2

Table 2: Test results of cupping 7mm at different speeds & Test results of cupping 10mm at different test panels of different thicknesses

Conclusion: As can be seen from the above table, the cupping value increases with the increase of the sample thickness. The optimal cupping speed is controlled at 0.1-0.2mm/s.

3 Factors affecting the test process and solutions

3.1 The temperature and humidity of the test environment directly affect the test results.

Solution: The test should be carried out in a constant temperature and humidity room at 23±2℃ and a relative humidity of (50±5)%.

3.2 The distance between the intersection of the test panel and the center axis of the punch should not be less than 35mm.

Solution:When selecting the test panel, the side length should not be less than 70mm.

3.3 Zero calibration affects the test results.

Solution: Use a calibration panel to calibrate the instrument before testing.

4 Comparative analysis of Automatic Cupping Tester and traditional manual cupping tester

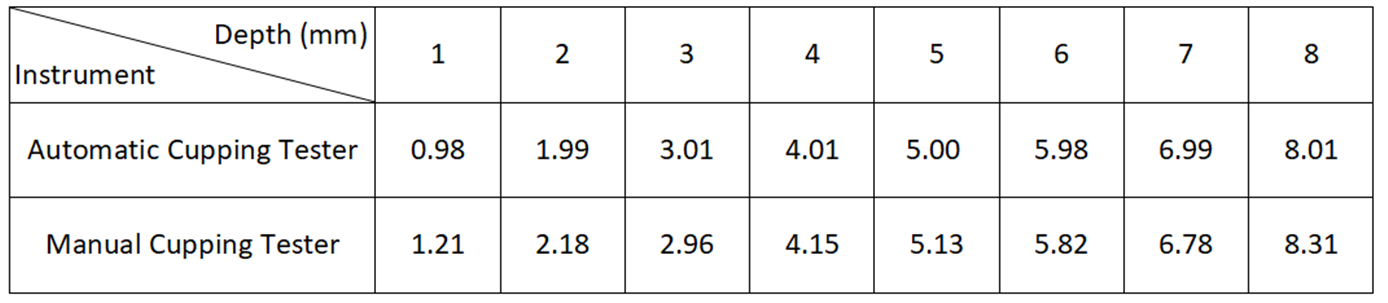

4.1 The results of cupping tests of the same test panel at different depths using Automatic Cupping Tester and traditional manual cupping tester are shown in Table 3.

Table 3: Comparative test of Automatic Cupping Tester and traditional manual cupping tester

Conclusion: From the above table, it can be seen that the cupping value of the same test panel at different depths is more accurate than that of the cupping value of the traditional cupping instrument.

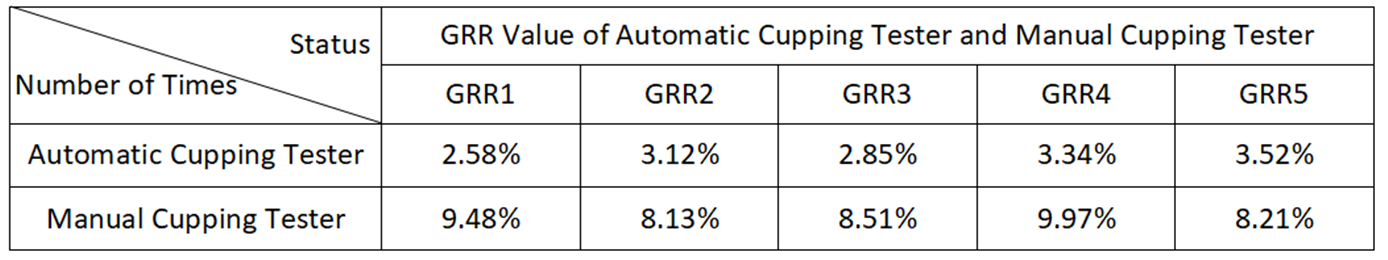

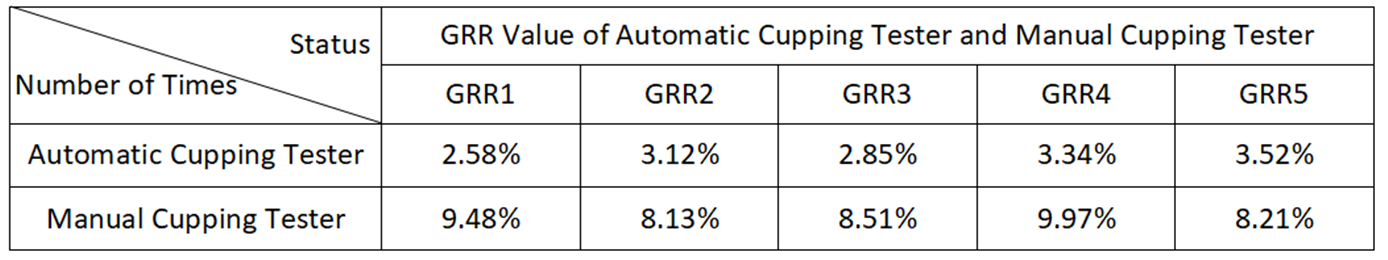

4.2 Repeatability comparison test was performed using the Automatic Cupping Tester and the Manual Cupping Tester, as shown in Table 4:

Table 4: Comparison of GRR value test between the Automatic Cupping Tester and the Manual Cupping Tester

Note: GRR refers to the repeatability and reproducibility of the measuring tool. The GRR value determination method is: GRR=<5% The repeatability of the testing equipment is very good, GRR=<10% The testing equipment is acceptable, 10%<GRR<20% GRR="">=20% The testing equipment is unacceptable and needs to be improved; From the above GRR values, it can be seen that the repeatability of the intelligent cupping instrument is much better than that of the manual cupping instrument.

5 Advantages of automatic cupping test

5.1 The worm gear is used for motor drive, which makes the test results accurate, and the speed can be selected between 0.01-0.4 mm/s for cupping. The tester uses a touch screen for operation, simple and easy.

5.2 The mechanized automatic operation device is used to ensure that the running speed and force are uniform, which greatly improves the authenticity and accuracy of the test results.

5.3 The cupping stroke and running speed can be pre-set, and the equipment running status can be "automatically reset" after the test. The test results can be transferred to the PC for analysis and generate a test report.

5.4 The Automatic Cupping Tester is also equipped with a set of LED visual observation system, which makes the test results more intuitive and easy to understand. The brightness of the LED light can be adjusted to obtain contrast. It ensures that the results of various types of surfaces such as high gloss, matte, and rich colors are observed to the maximum extent.

1 The Automatic Cupping Tester is operated by a touch screen, which is both user-friendly and intelligent.

2 Video and photo recording can be performed during the cupping process so that the image can be copied to a USB flash drive (traditional cupping instruments do not have video and photo recording functions). It can help users more intuitively observe the tensile cracking and peeling strength of metal surface coatings and related products from the substrate, and provide customers with test storage.

3 When a constant speed is set (traditional manual cupping instruments cannot set a constant speed), the Automatic Cupping Tester is more accurate than the traditional cupping instrument in the cupping stroke.

4 During the cupping process, the Automatic Cupping Tester achieves uniform cupping through program control, and the measured results are closer to the actual value.

5 The Automatic Cupping Tester also adds real-time cupping process output to the computer, which greatly improves the image resolution and clarity, and can obtain clear photos and videos on the computer, it can facilitate future tracing.