Equipos

- Dispersión

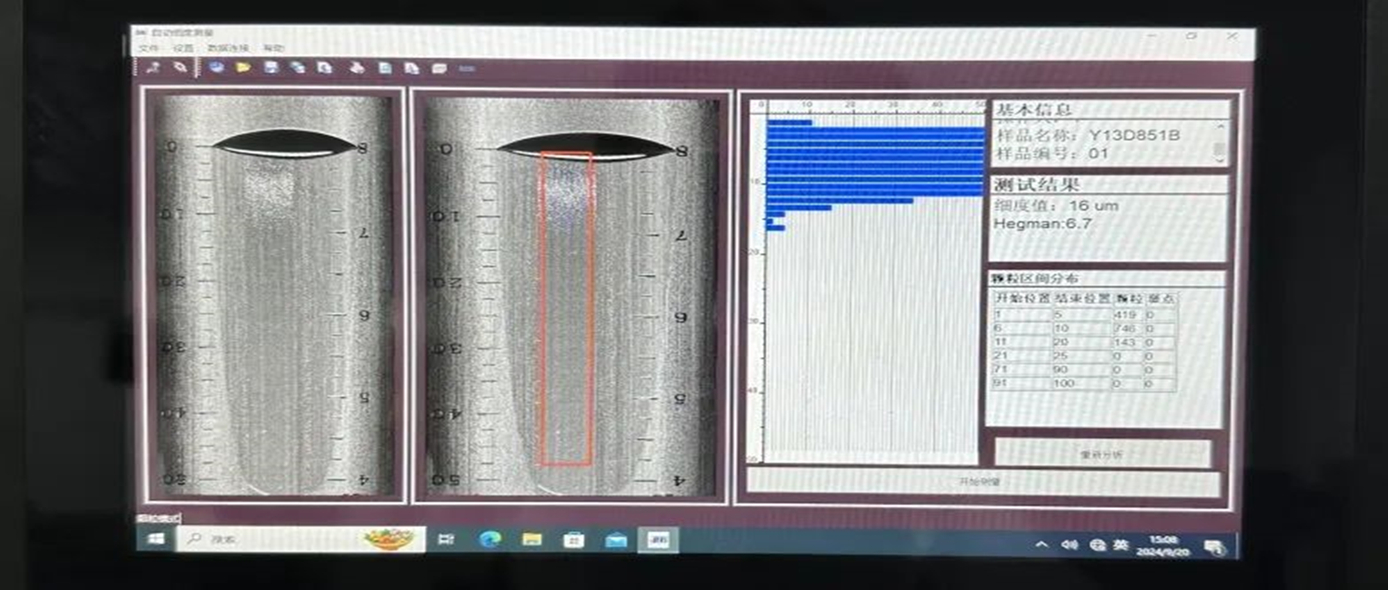

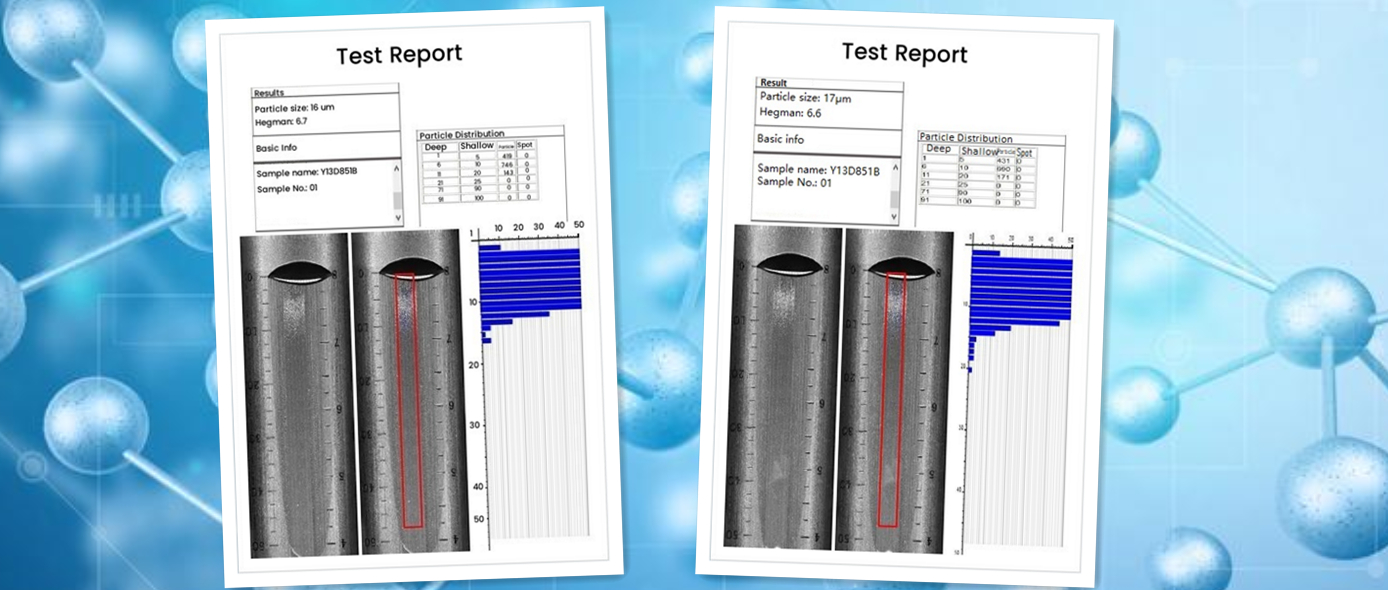

- Densidad / Finura

- Viscosidad

- Aplicación de recubrimiento

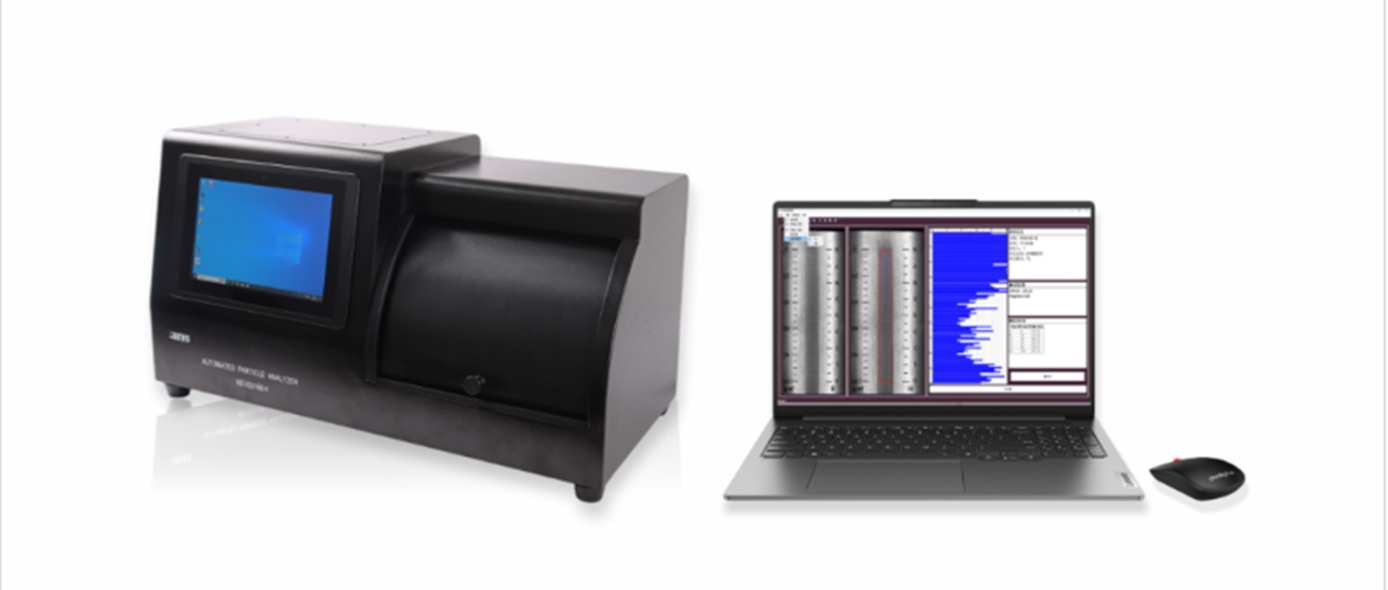

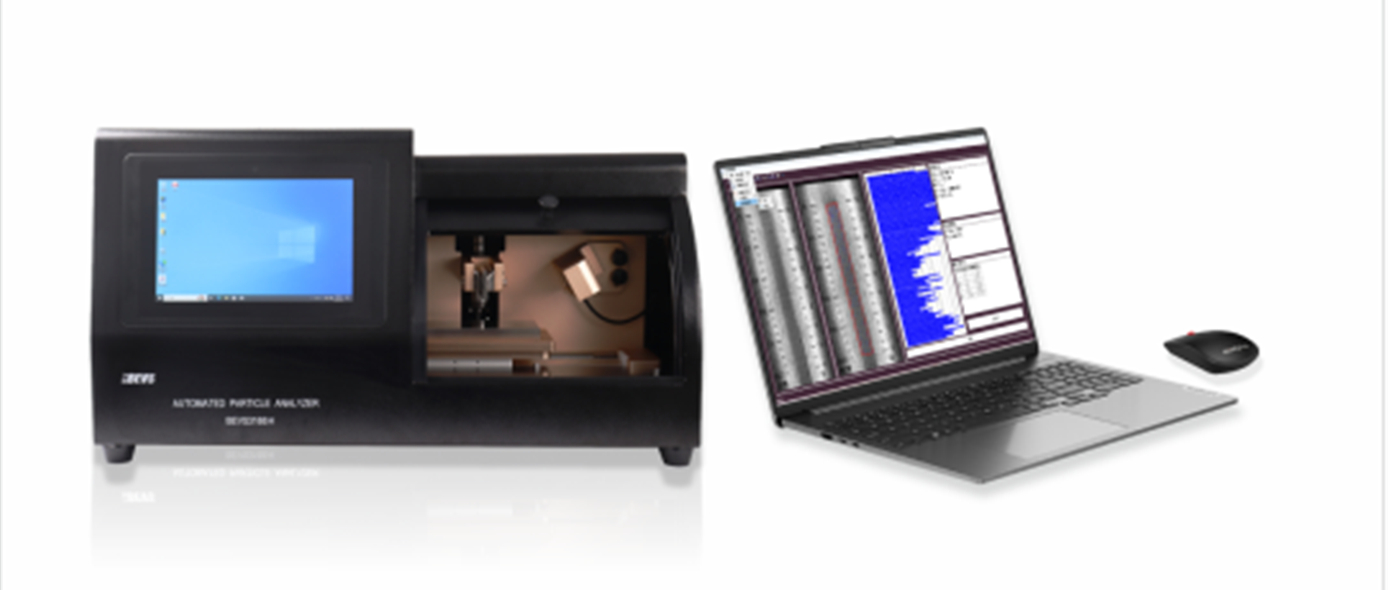

- Aplicador de recubrimientos automático compacto

- Aplicadores de recubrimientos automáticos

- Aplicadores de barra

- Aplicador forma “U”

- Aplicador cilíndrico (4 caras)

- Aplicador de cuatro lados con depósito

- Aplicador de forma cúbica

- Aplicador de altura ajustable

- Aplicador de descuelgue

- Aplicador de nivelación

- Varillas de espiral

- Soporte de varillas

- Cartulinas de ensayo

- Aplicador ajustable digital

- Kit de aplicación

- Cabina de aplicacion para paneles con pintura liqu

- Tiempo de secado

- Espesores

- Temperatura

- Color y Brillo

- Adherencia

- Dureza

- Deformation

- Abrasímetro, frote y lavabilidad