Definition of Coating Abrasion Resistance

The resistance to abrasion is a measure of the difficulty of obtaining a smooth and matte surface during the coating process of coating products by grinding materials such as sandpaper or pumice on the paint film or putty layer. It reflects the comprehensive effect of multiple performance parameters such as hardness, adhesion, and cohesion of the coating. This performance indicator is crucial for coating engineering, especially in the application of primer and putty.

In the automotive manufacturing industry, furniture industry, and other fields that require long-lasting appearance, good wear resistance can maintain the beauty of coatings and prevent scratches and wear caused by daily use. For some special purpose coatings, such as floor coatings, optical displays, etc., wear resistance is a key factor in ensuring that their functionality can be maintained for a long time.

To accurately measure the abrasion resistance of coating films, the International Organization for Standardization (ISO) and the National Standardization Organization of China (GB/T) have released a series of related standards. Below are some standards related to coating film abrasion resistance:

1. GB/T 1770-2008 "Determination of abrasion resistance of Coatings and Putty Films": This is a national standard in China that specifies the method for determining the abrasion of coatings and putty films. It involves fixing the sample on the suction cup and installing a specified type of water sandpaper or cloth on the grinding head of the instrument. Counting is done through a reader, and the friction speed and pre friction times are selected to evaluate the sanding performance of the paint film.

2. GB/T 1768-2006 "Determination of abrasion Resistance of Coatings and Varnishes by Rotating Rubber Grinding Wheel Method": This standard specifies the use of rotating rubber grinding wheel method to determine the wear resistance of coatings and varnishes. The wear resistance is evaluated by measuring the weight or color change of the sample before and after wear.

3. GB/T 23988-2009 "Determination of abrasion Resistance of Coatings - Falling Sand Method": This standard provides another method for determining the abrasion resistance of coatings, namely the falling sand method, which is suitable for evaluating the abrasion resistance of coatings in actual use.

4. ISO/TR 21555:2019 "Overview of Test Methods for Hardness and abrasion Resistance of Coatings on Paints and Varnishes": This is an international standard that outlines the testing methods for coating hardness and abrasion resistance. It provides an introduction to different testing methods to help users choose the testing method that suits their needs and improve the reliability and accuracy of test results.

5. ISO 7784-2:2016 "Determination of Resistance to abrasion of Paints and Varnishes": This standard is part of surface abrasion testing, particularly the rotating method, used to test the wear resistance of paints and varnishes.

6. ASTM D 8380-21 "Hydrophobic and Fully Hydrophobic Dry abrasion Resistant Coatings": This standard is used to evaluate the dry friction performance of thin hydrophobic or pan hydrophobic coatings.

Key points of testing methods

Referring to GB/T 1770-2008, we will now introduce how the method is used to test the abrasion resistance of coating films.

1. Testing principle

An empirical test method for evaluating the abrasion resistance of coatings and putty films under specified loads, after a specified number of passes, based on the changes in the surface of the coating and the difficulty of polishing.

2. Materials and equipment

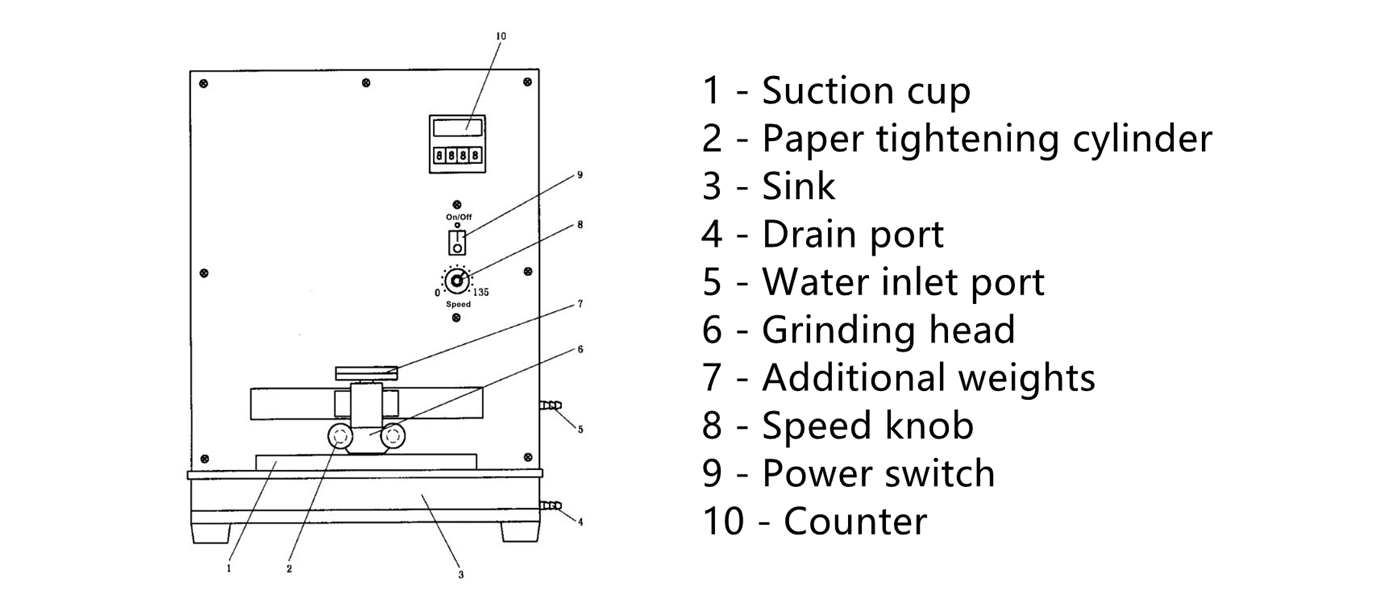

A. Abrasion tester

Speed: 0-135 times/min (one-way);

Stroke: 155 mm ± 5 mm (one-way);

Cycles range: 0~9999 (two-way counting);

Abrasion head load: 570g ± 20g;

Additional weight load: 50 g, 100 g, 200 g

B. Water sandpaper or sandpaper cloth

The specifications and models shall be determined or agreed upon according to the product standards.

C. Sample preparation

According to the provisions of GB/T 3186, take representative samples of the tested product.

According to the provisions of GB/T 20777, inspect and prepare test samples.

The size of the tinplate or steel plate that meets the requirements of GB/T 9271 is 200 mm x 80 mm.

Process each test panel according to the provisions of GB/T9271

3. Key points of operation

l Place the test panel in the center of the suction cup, so that the test panel is adhered to the suction cup.

l Select water sandpaper or sanding cloth of the specified specifications and tighten and fix it on the abrasion head.

l According to the different coatings and putty films, weights should be added and placed on the abrasion head.

l If wet abrasion is required, connect the inlet and outlet pipes, adjust the water flow rate so that it can be continuously dripped onto the polishing head; If dry abrasion is required, do not drip water.

l Use a counter to set the number, select the speed and cycles.

l Turn on the instrument and observe the test panel after reaching the predetermined number of cycles.

4. Result evaluation

Visually observe under scattered sunlight and evaluate the results based on two samples with similar phenomena among the three samples. According to the needs, the phenomena that appear on the surface of the sample coating after polishing can be evaluated, such as whether the surface is smooth, whether there are unpolished pigment particles or other impurities. The difficulty of polishing can also be evaluated based on the weight loss of the coating before and after polishing or the degree of adhesion of abrasives on the sandpaper.

5. Influencing factors

Preparation of sample: The surface condition, thickness, and dryness of the sample will affect the results of the abrasion resistance test. If the surface of the sample is uneven or the thickness is uneven, it may lead to inaccurate test results.

The selection of sandpaper: The particle size and material of sandpaper have a direct impact on the test results. Different grit sandpapers have varying degrees of wear on the paint film, so choosing the appropriate sandpaper is crucial for obtaining accurate test results.

Load pressure: The pressure applied during the testing process can affect the polishing effect. If the pressure is too low, it may not be possible to fully polish the paint film; Excessive pressure may lead to excessive wear of the paint film.

Abrasion speed and cycles: The speed and cycles are also influencing factors. Excessive speed or polishing too many times may cause excessive wear on the surface of the paint film, affecting the accuracy of the test results.

Environmental conditions: The temperature and humidity conditions during testing may affect the performance of the paint film, thereby affecting the test results of abrasion resistance. The hardness and flexibility of the paint film will vary under different temperature and humidity conditions.