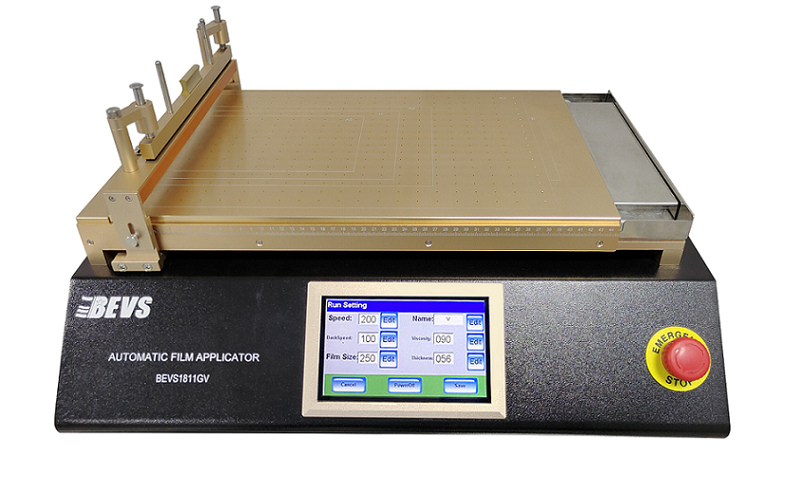

Automatic Film Applicator

How to choose an Automatic Film Applicator?

Automatic Film Applicator is a commonly used laboratory equipment. Currently, there are many kinds of this machines on the market. There are glass beds, as well as vacuum beds, with diverse functions and significant price differences. When choosing an Automatic Film Applicator, users may encounter some problems. What is good and how can they choose a high-precision one?

Principles of Automatic Film Applicator

Automatic Film Applicator is a laboratory instrument that is used to uniformly apply liquid coatings, inks, glues, and other substances on the surface of test substrates to prepare a uniform and traceable coating for repeated testing of coating thickness, color, quality, and other properties. It can be used for film application and quality control in industries such as paints, inks, plastics, cosmetics, and medical devices etc.

By simulating manual operation, the machine can minimize or eliminate errors caused by factors such as drawdown speed, direction, and applied pressure in a more uniform and constant manner. The machine itself does not control the film thickness, and is generally equipped with high-precision small applicators and bar coaters to control the film thickness to attain a required coating.

Composition of Automatic Film Applicator

1. Host machine with touch screen: controls the experimental process and data storage.

2. Drawdown platform: used to place the test substrate.

3. Clamp: used to fix the test substrate.

4. Push rod: used with a weight to push in a straight line at a set speed.

5. Loading weight: apply pressure onto the small applicator.

6. Anti-dripping pan: collect excess test samples.

7. Vacuum pump (optional): used with a vacuum bad to fix the test substrate.

Application of Automatic Film Applicator

Raw material manufacturers in the paint industry, such as adhesives, pigments, additives, colorants, solvents, and resins, require a large number of repeatable films to ensure the stability and product quality of paints during the production process.

Automatic Film Applicator can produce a large number of consistent films for measuring the performance of cosmetics and skin care products, such as hardness, breaking strength, consistency, compaction strength, hiding power and opacity, spreading ability, viscosity, drying and curing time, color, gloss, and so on.

When bonding, not only normal temperature required for bonding test, but also high and low temperatures do. Automatic Film Applicator with heating vacuum bed can offer different temperatures for the test.

Selection Steps of Automatic Film Applicator

The selection is relatively simple. Generally, it is based on the characteristics of the test substrate and test material to select an Automatic Film Applicator. Take Guangzhou BEVS Automatic Film Applicator as an example:

Step1: Confirm the size of the substrate

Select models of different sizes based on the size of the test substrate

1) Mini model (320 x 220mm): Suitable for standard size test substrates.

2) Standard model (420 x 300mm): Suitable for A5/A4/A3 paper, hiding power chart, black plastic panel, etc.

Step 2: Confirm the thickness and softness of the substrate

Select different test beds based on the thickness and softness of the test substrate

1) Glass bed: Suitable for standard size test substrates.

2) Vacuum bed: Suitable for thin, soft, and uneven surface substrates like thin film, plastic sheet, aluminum foil, copper foil, etc.

3) Glass + vacuum bed: Wide application range.

Step 3: Confirm the characteristics of the test material

Select models with different drawdown speeds based on the characteristics of the test material

1) Standard type (1~200 mm/sec): Suitable for conventional test materials, with a minimum film speed of 1 mm/sec, which meets high precision requirements (like film and roll).

2) High speed type (1~350mm/sec): suitable for a variety of test materials, with a drawdown speed of up to 350mm/sec, especially suitable for fast drying materials.

Step 4: Confirm heating function if required

The heating function of BEVS machine ranges from ambient + 5 to 200 ℃, suitable for testing materials that require a certain temperature to maintain a molten state.

Step 5: Confirm the film thickness

According to the required film thickness, select different widths and thicknesses of small film applicators. Generally speaking, bar coaters are suitable for testing materials with low viscosity, while other like one/two/four sided film applicators and adjustable film applicators are suitable for testing materials with high viscosity.

What other details should pay attention to when purchasing?

Testing instrument is a specialized product. In addition to the selection steps mentioned above, it is recommended that to choose a professional manufacturer and purchase it through formal channels. Secondly, also pay attention to the brand reputation, after-sales service, and other aspects, and do not take price as the priority.