Aging test of polymer materials

Current status of polymer materials

Polymer materials, due to their light weight, high strength, temperature resistance, corrosion resistance and other excellent properties, are now widely used in high-end manufacturing, electronic information, transportation, construction, aerospace, national defense and military industry and many other fields. Therefore, how to maximize the function of polymer material products receives much attention. And aging is an important factor that affects the reliability and durability of polymer materials.

Aging test of polymer materials

Types of aging of polymers

Due to the difference in varieties and end-use environment, polymers have distinctive aging features. In general, the aging of polymer materials can be categorized into the following four types:

*

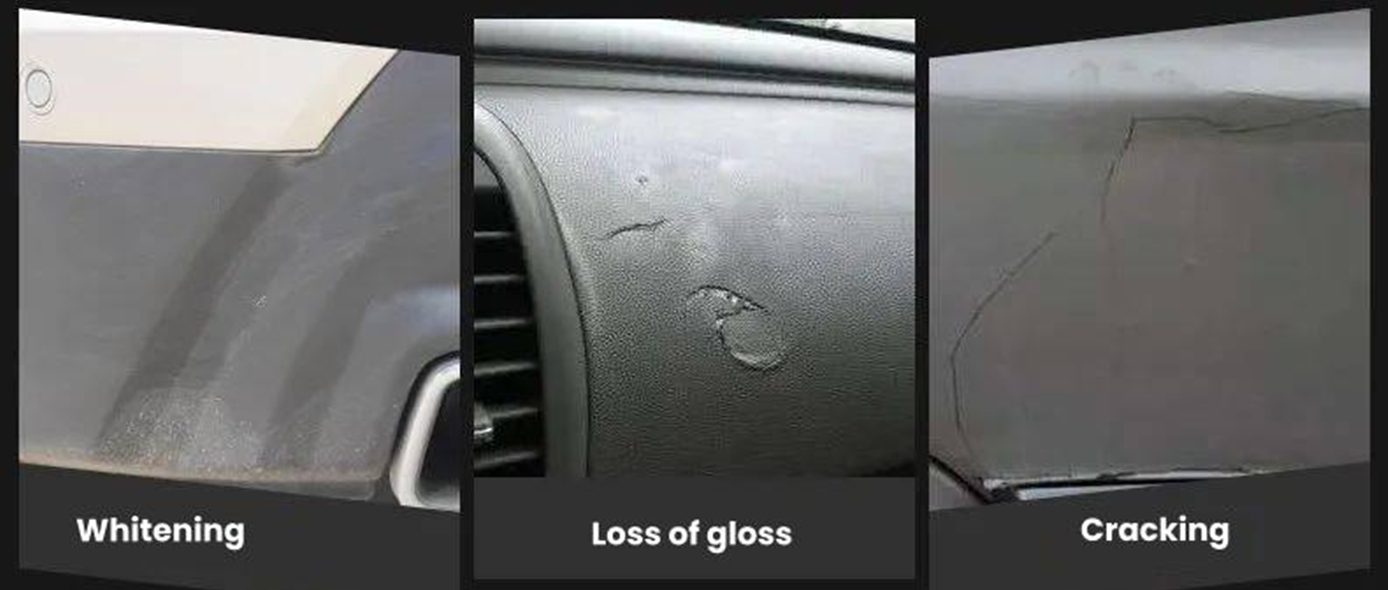

Changes in appearance

Stains, spots, silvering, cracks, frosting, chalking, sticking, warping, wrinkling, shrinkage, scorching, optical aberrations, and changes in color.

*

Changes in physical properties

This includes changes in solubility, swelling, rheological properties, and cold resistance, heat resistance, water permeability, and air permeability.

*

Changes in mechanical properties

This includes tensile strength, flexural strength, shear strength, impact strength, relative elongation, and stress relaxation.

*

Changes in electrical properties

This includes surface resistance, volume resistance, dielectric constant, and electrical breakdown strength.

Aging test of polymer materials

Principle of the aging of polymer materials

Polymers form excited-state molecules in the presence of heat or light, and when the energy is high enough, the molecular chains break to form free radicals, which can form chain reactions within the polymer that continue to initiate degradation and may also cause cross-linking.

If oxygen or ozone is present in the environment, it also induces a series of oxidation reactions that form hydroperoxides (ROOH), which further decompose into carbonyls.

If residual catalyst metal ions are present in the polymer, or if metal ions such as copper, iron, manganese, cobalt, etc. are added during processing or use, the oxidative degradation reaction of the polymer will be accelerated.

Aging test of polymer materials

Aging Test

In the development or improvement of new materials, weathering tests are required to verify their service life or anti-aging effects. Common weathering tests are natural aging test and accelerated laboratory aging test.

Natural aging test

It involves direct exposure of material samples to the natural environment. Usually the samples are mounted on an exposure rack at an angle, with common exposure angles of 5°, 45° and 90°. Relevant test standards are ISO 877 Plastics - Methods of exposure to solar radiation; ISO2810 Paints and varnishes - Natural weathering of coatings - Exposure and assessment; ASTM Doppler - Exposure to solar radiation; and ASTM Doppler - Exposure and assessment. Exposure and assessment; ASTMG7 Standard Practice for Atmospheric Environmental Exposure Testing of Nonmetallic Materials and so on.

This method is simple and cost-saving, but its test cycle is too long, which affects the progress of product design. Moreover, since it is conducted in the natural environment, the climatic conditions cannot be controlled, and in order to ensure the reproducibility of the test results, the selection of the test site is particularly important.

Laboratory accelerated aging

In order to speed up the test cycle and get the aging data quickly, the laboratory accelerated aging test usually uses artificial light source to simulate daylight radiation, combined with different temperature, humidity, rain, and etc., to simulate a variety of natural climate conditions.

1

Selection of light source

Commonly used artificial light sources include xenon arc lamps, metal halide lamps and UV fluorescent lamps. Ultraviolet fluorescent lamps can simulate daylight well in the mid-wave ultraviolet and short-wave ultraviolet regions. Xenon arc lamps and metal halide lamps, on the other hand, simulate daylight well in the full spectrum. In addition, there are also aging chambers that use carbon arc lamps as light sources. However, the carbon arc spectrum does not correlate well with the daylight spectrum. The use of carbon arc lamp testing is for historical reasons.

2

Relevance of accelerated aging

Correlation refers to the degree of consistency between the results of accelerated aging test in the laboratory and the results of aging test of the material in the end-use environment. Accelerated aging test, only with correlation, can truly reflect the weathering performance of the material and predicate the service life of the material. Unreasonable accelerated test will reduce the relevance of the test, and even loses its meaning.

Aging test of polymer materials

The trend of laboratory accelerated aging test

As mentioned in the opening paragraph, the aging of materials is influenced by solar radiation, temperature, water and other factors. The aging of materials is the result of a combination of these factors, but it is not simply a superposition of the effects of the various factors, but also needs to take into account the synergies between them. Therefore, a more comprehensive simulation of the actual environment in which the material is used can lead to results with better correlation. For example, according to ISO 20340, the test is conducted in a 7-day cycle, with UV testing in a light/dark cycle from day 1 to day 3 according to ISO 11507, then conducting salt spray testing on day 4 to 6 according to ISO 9227, and performing low-temperature testing at -20±2°C on day 7. Compared with the traditional weathering test, it integrates more factors and is more in line with the actual working conditions of the material, thus better reflecting the actual aging of the material. We know that mold, ozone concentration, etc., have an important impact on the aging of plastic products. So how to integrate more factors in the test will be one of the directions of the laboratory accelerated aging.