Have you encountered product rework due to inadequate coating wear resistance? Or performance issues stemming from easily abraded textiles? In today’s highly competitive manufacturing environment, material wear resistance is a critical factor influencing product durability and overall quality perception.

We now introduce a next-generation abrasion testing instrument that redefines conventional testing paradigms —— BEVS 2816 AI Rotary Abraser. Enhanced by AI-driven algorithms, this system delivers higher testing accuracy, real-time data analysis, and improved repeatability—empowering R&D and QA laboratories to optimize workflows, reduce testing costs, and accelerate product development cycles.

Powered by Intelligence

✅ Intelligent Operation — Minimize Manual Effort

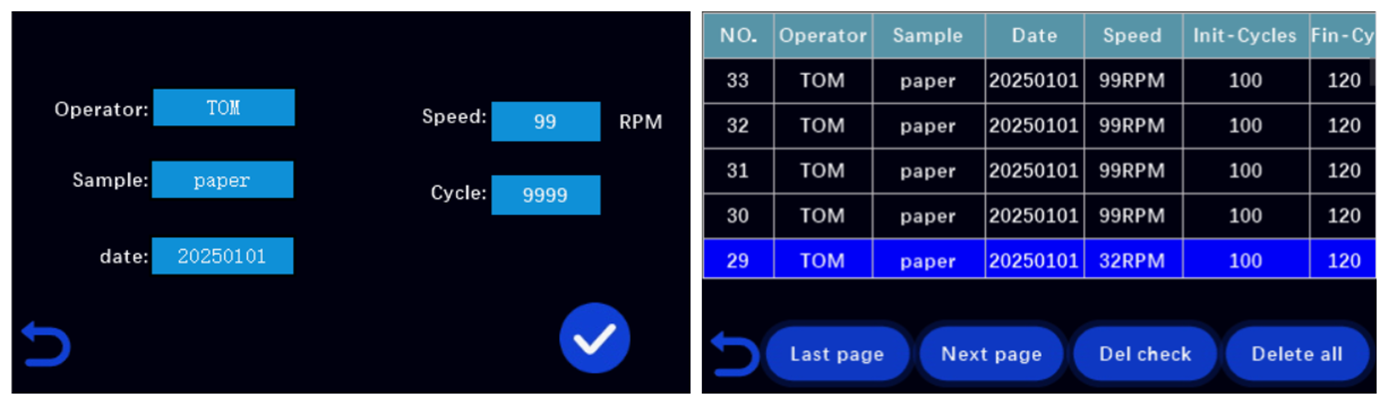

AI Voice + Touchscreen Dual Control: Fully visualized interface with voice command enables easy operation, even for non-specialists.

Auto Counting & Reset: Set the desired cycle count; the system runs automatically and displays results upon completion—reducing human error.

✅ High Precision — Reliable, Standardized Results

Dual Abrasive Wheel System: Fully compliant with GB/T 1768, ISO 7784, and other international standards. Compatible with over 10 material types including leather, coatings, plastics, and textiles.

Adjustable Load Mechanism: Includes a standard set of calibrated weights for variable testing conditions.

✅ Clear Data Management — At a Glance

IoT-Enabled LIMS Integration: Real-time monitoring of device status with support for data export and statistical analysis.

Auto Data Storage: Capable of storing up to 1,000 test records, ensuring traceability and easy retrieval.

△User-friendly interface

✅ Efficient Cleaning — Save Time and Effort

External Dust Collector Included: Comes with a dedicated vacuum unit that actively removes debris during testing, helping to prevent dust contamination of both samples and equipment.