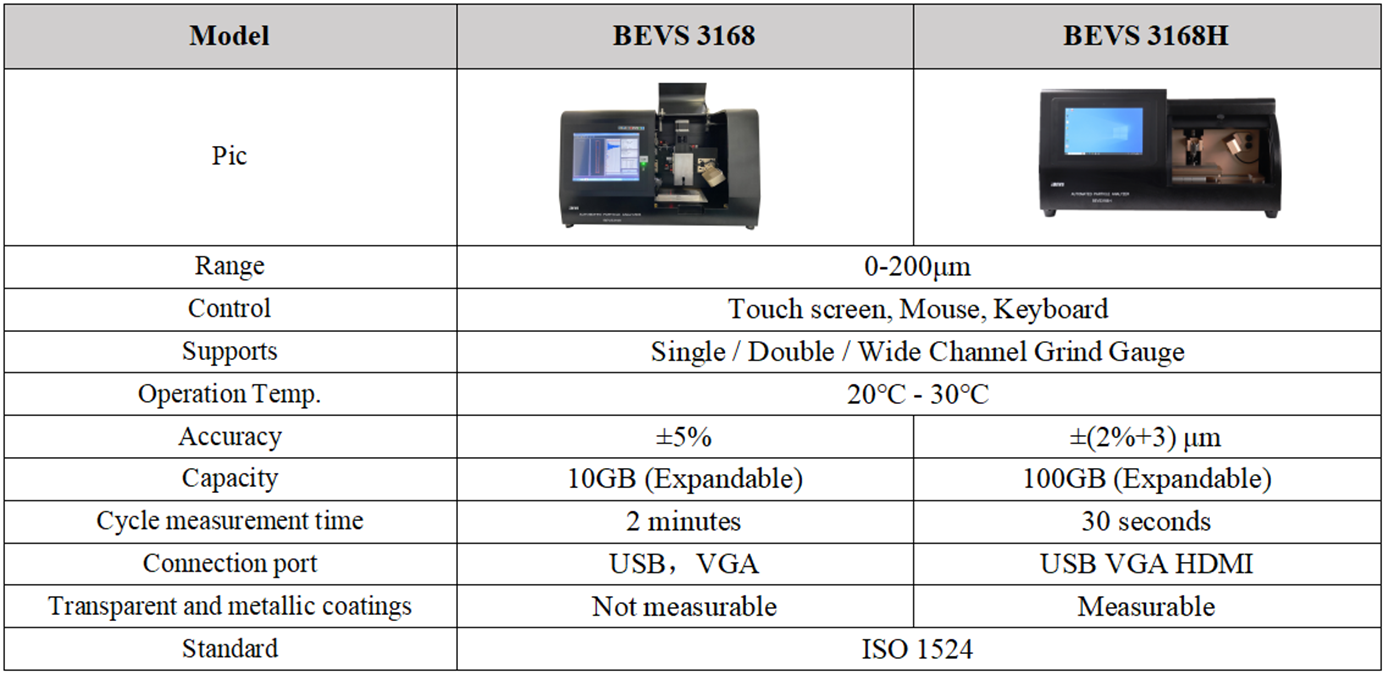

In the coatings industry, accurate measurement of fineness is crucial to ensure product quality. In 2016, BEVS launched BEVS 3168, the first Automated Particle Analyzer, which perfectly combines automation technology with high-precision measurement. Besides, it breaks through many limitations of traditional measurement methods, making it an eye-catching solution for customers.

Since its first debut 8 years ago, BEVS 3168 has earned a good reputation and trust from clients for its stable performance, accurate testing result, and efficient automating operations.

BEVS launched BEVS 3168H, a new generation of Automated Particle Analyzer, in August 2024 after 8 years of experience and research. Apart from the revolution in appearance, configuration and performance, this newly upgraded instrument enables automatic drawdown, automatic measurement and analysis.

What are the highlights of the BEVS 3168H? Let's take a look!

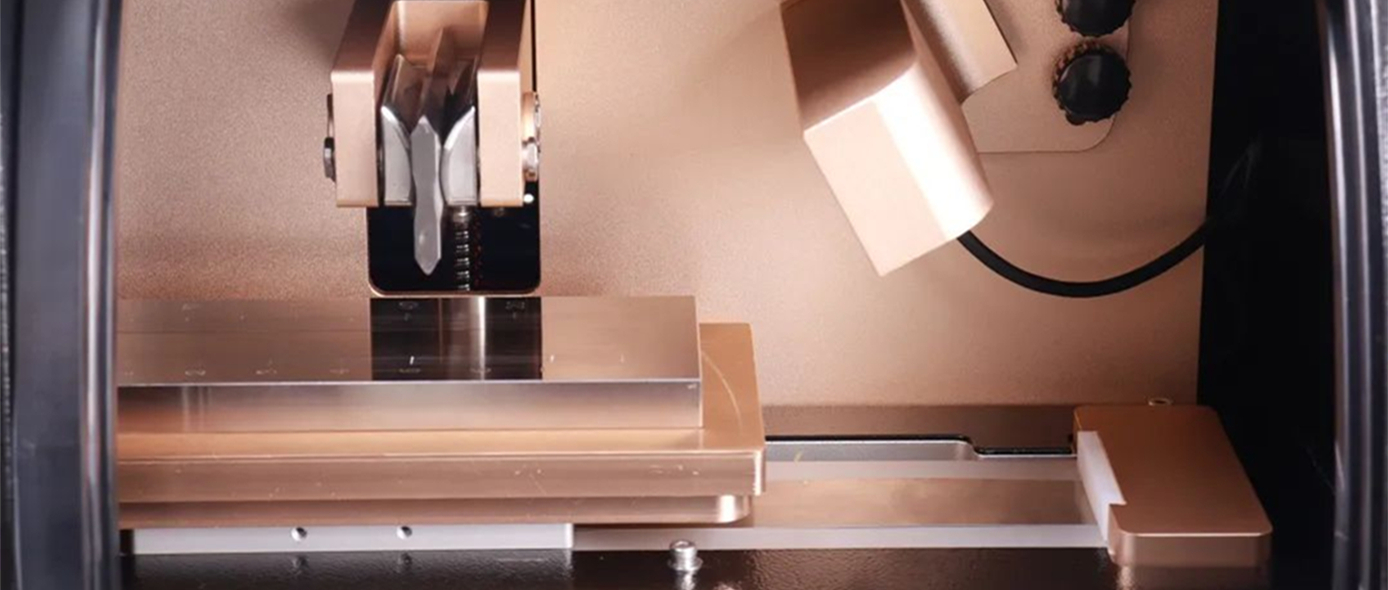

BEVS3168H employs a new exterior, making the whole machine design more humane. The flip cover of the test chamber on the right side changes into slider cover from the flip type to slide type, delivering easier operation.

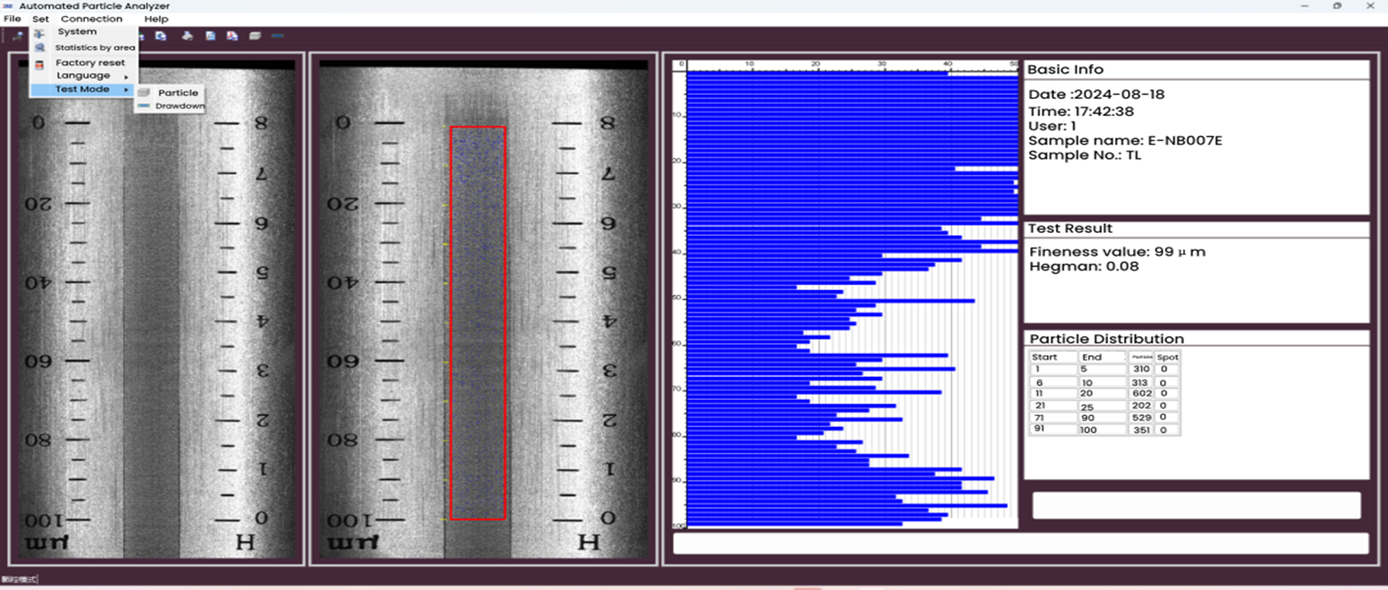

BEVS 3168H adopts a new operating software and it is fitted with a 10-inch high-definition touch screen, which presents users with the test results, such as particle size distribution graphs, scratch distribution graphs, etc., providing strong support for R&D and quality control.

Equipped with a 4K high-definition camera and an advanced sensor, it provides high transmission speed and super-sharp images. Measurement accuracy is raised from ±5% μm to ±2% μm, with a repeatable accuracy of ±3 μm, which realizes higher precision measurement.

Leading sensing technology and data processing algorithms make it possible to measure common coatings and coatings with special effects, such as transparent liquid materials and metallic paints.

A single measurement takes only 30 seconds, dramatically increasing testing efficiency and making the laboratory testing process faster.

The storage capacity is expanded from 10GB to 100GB and offers three different connection ports, USB, VGA, and HDMI, to meet more needs.

Coatings, Resins, Pigments, Polymers, Titanium dioxide, Cosmetics, Pharmaceuticals, Food, Electronic materials, Chip materials, etc.

We know that in the coating industry, innovation is the pursuit of perfection. The launch of BEVS 3168H Automated Particle Analyzer not only improves the efficiency of the laboratory testing, but also enhances the stability of product quality. We believe that it will become an indispensable partner in your laboratory and create a new chapter of coating measurement with you.