In modern scientific research and industrial production, coating technology plays a crucial role, with high-quality coating processes being key to ensuring product performance. The BEVS 1818GV Mini Automatic Film Applicator, a high-precision device designed specifically for laboratories and small-scale production, has become an innovator in the field of coating technology due to its exceptional performance and versatility.

Mini Automatic Film Applicator is a laboratory instrument used to evenly coat liquid paints, inks, adhesives, etc., on test substrates to prepare uniform and traceable films. This allows for repeated testing of coating thickness, color, quality, and other performance metrics. It is applicable in industries such as coatings, inks, plastics, cosmetics, and medical devices for coating applications and quality control.

Automatic Film Applicator simulate manual operations, applying force more evenly and at a constant speed to minimize or eliminate errors caused by human factors such as coating speed, direction, and applied pressure. The coating machine itself does not control film thickness; it is typically paired with high-precision applicators and bar coaters to enhance coating accuracy. Its unique low-speed operation capability ensures smooth and steady performance at a speed of 1mm/s, achieving optimal performance for low-speed film preparation. The user-friendly large LCD screen features touch-screen operation and supports both Chinese and English language options.

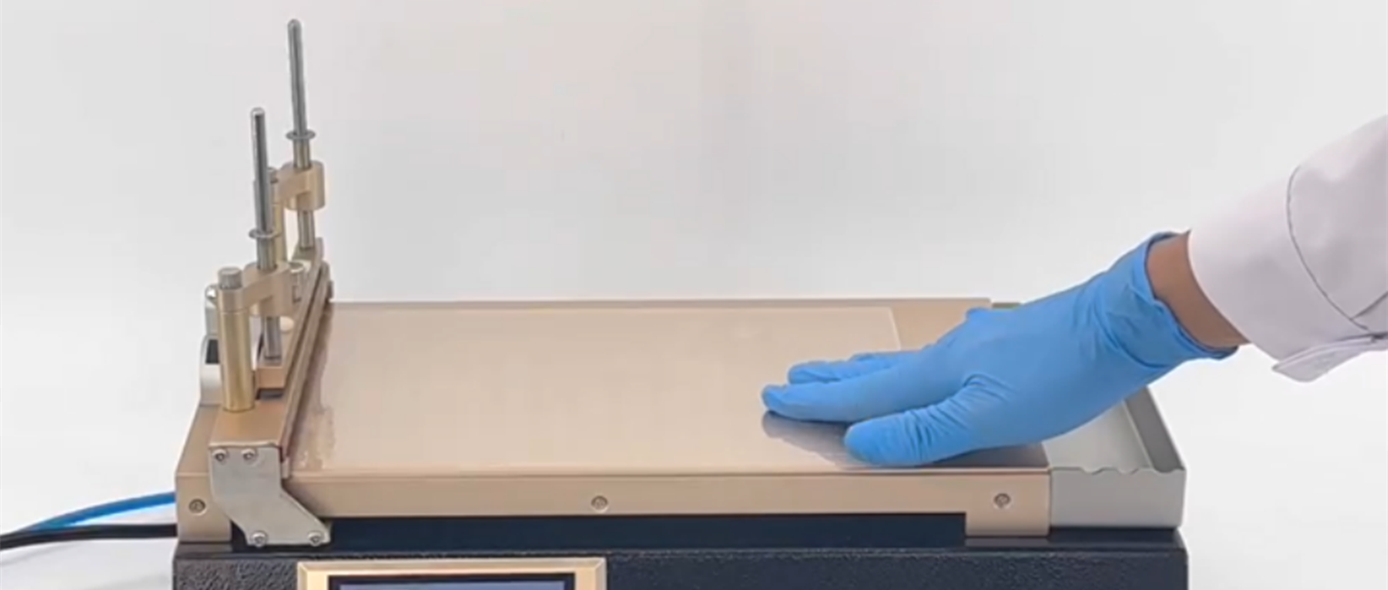

1. Wipe the vacuum test platform clean, as dust on the platform may affect the coating results.

2. Connect the power supply and turn on the instrument's power switch. Check whether the emergency stop button is in the normal state. If the emergency stop button is pressed, rotate it clockwise to restore it to the normal state.

3. Connect the vacuum pipe and turn on the vacuum pump power (external vacuum pump).

4. Place the substrate for coating on the test platform and secure it. It can use the clamps on the test platform to press the substrate or use vacuum suction to hold the substrate in place.

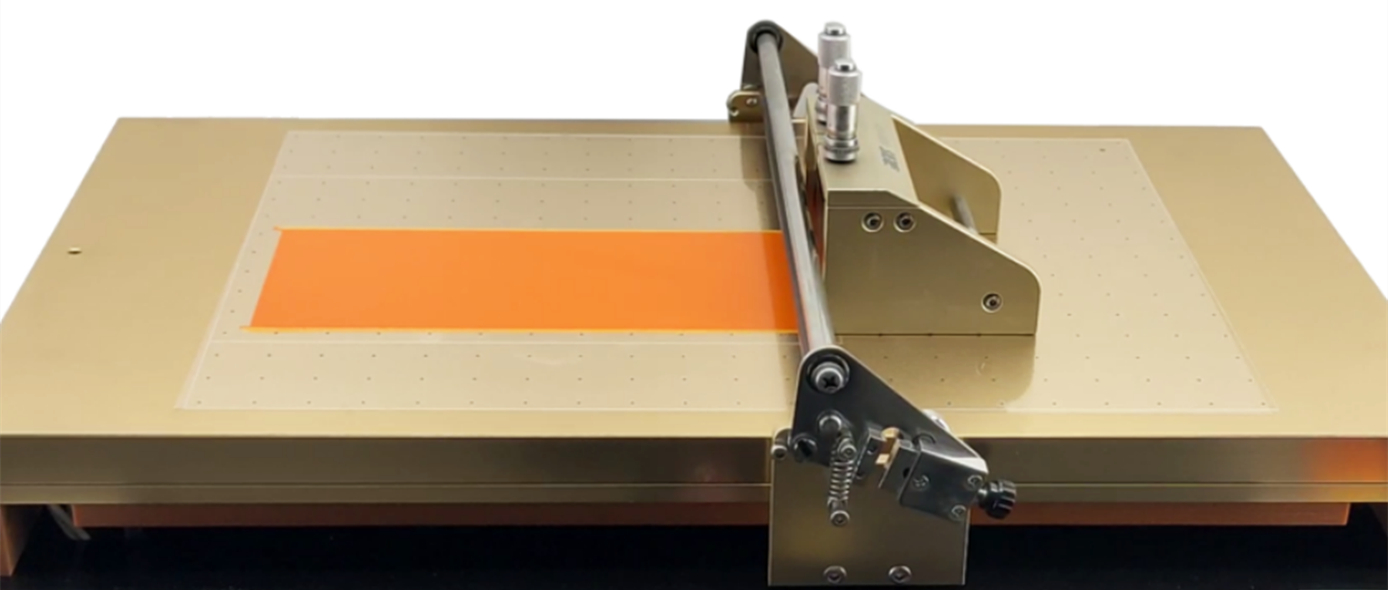

5. Select an appropriate coating applicator. When using the applicator to prepare films with high-viscosity coatings, if additional weight needs to be loaded onto the applicator, follow these steps:

(1) Loosen the hand-tight screw at the front of the clamping device, lift the handle, rotate the clamping device, and press it onto the applicator.

(2) Add weights to the weight shaft (the amount of weight can be adjusted as needed).

(3) Tighten the hand-tight screw to secure the clamping device. During this process, handle the weights gently to avoid damaging the instrument.

6. Place an appropriate amount of coating sample in front of the applicator, set the coating parameters, and click the "Start" button on the touch screen to begin the coating process.

7. After the coating is completed, if the clamping device was used to secure the applicator, reset the clamping device first.

8. Click the "Return" button on the touch screen to reset the push rod, then remove the applicator, turn off the vacuum or release the clamping fixture, and take out the test plate.

9. Clean the instrument and the applicator, and then turn off the instrument.

1. This instrument is designed for laboratory use. The operating environment should maintain a temperature of 10°C to 35°C, humidity of 20% to 80% (non-condensing), wind speed of 0-0.2 m/s, and altitude below 2000 meters.

2. Do not operate the instrument in an environment with excessive vibration. Additionally, the operating environment should be kept clean.

3. Avoid placing heaters, radiation devices, or airflows near the instrument.

4. Avoid placing magnetic field sources, such as high-power motors or transformers, near the instrument.

5. Avoid placing water sources, such as faucets or sinks, near the instrument.

6. The instrument should be placed in an area without lightning protection measures.

Mini Automatic Film Applicator, with high-precision control, multifunctional applications, user-friendly design, and compact structure, have become leaders in the field of coating technology. Whether for research institutions or industrial enterprises, they provide efficient and reliable coating solutions, helping to elevate your R&D and production efforts to new heights.