Some plastics wear out quickly, while others can be used for extended periods under harsh conditions. This is due to the different resistance of materials to scratching abrasion. Wear resistance refers to a material's ability to withstand the gradual reduction in its surface volume caused by repeated friction, sliding, or scratching. Wear resistance can be divided into two types: dry abrasion and wet abrasion.

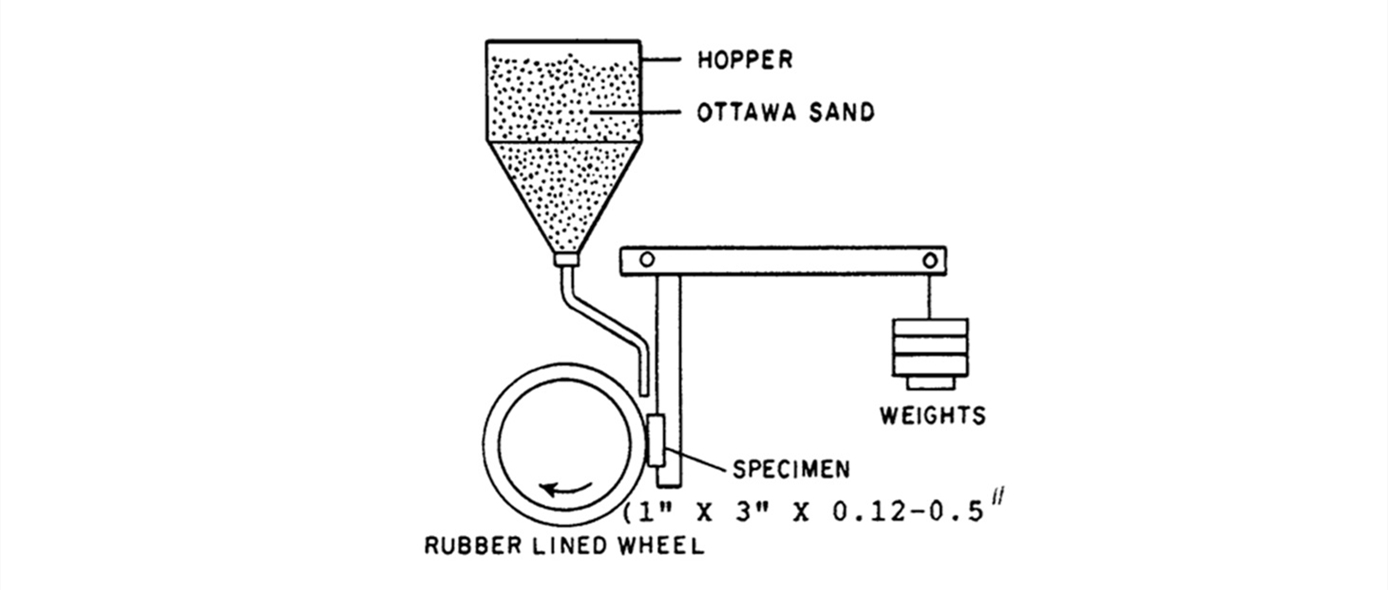

Dry abrasion occurs when dry abrasive materials friction against the polymer surface (Fig 1). This wear is common when polymers are exposed to solid particles like sand, dust, or dirt.

Fig 1. Schematic Diagram of Test Apparatus from ASTM G65

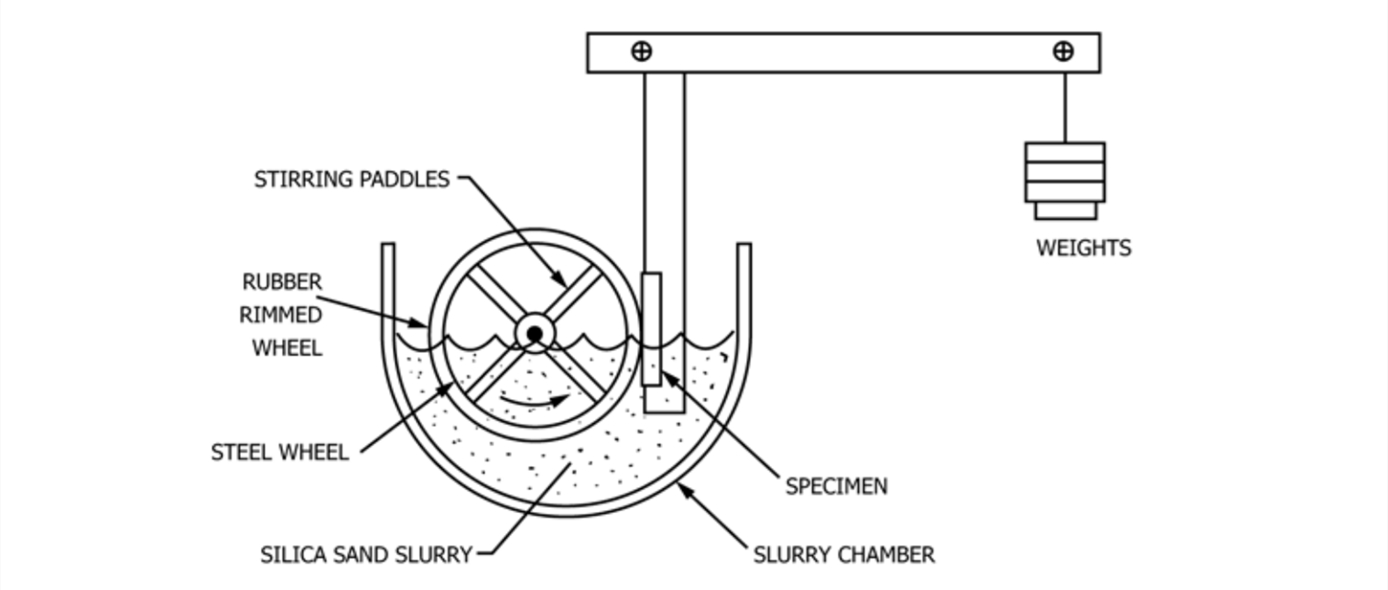

Wet abrasion involves the presence of a liquid, such as water or lubricant, during the abrasion process. The liquid can act as a carrier for abrasive particles or soften the polymer surface, making it more susceptible to wear (Fig 2).

Fig 2. Schematic Diagram of the Wear Test Apparatus from ASTM G105

How to Evaluate Plastic Wear Resistance?

Wear resistance is typically measured by mass loss, volume loss, or wear depth, depending on the specific testing method.

Common units:

Mass loss: grams per 1000 cycles

Volume loss: cubic centimeters per 1000 cycles

Wear depth: millimeters per 1000 cycles

The formula for wear resistance can vary depending on the specific testing method and required measurement units. However, a common method is to calculate the mass or volume loss rate per unit of wear.

What are the Testing Methods?

Many testing methods are used to evaluate the wear resistance of plastics. These tests measure the ability of polymers to resist wear caused by friction and abrasion.

Resistance to wear by abrasive wheels:

The method determines the wear resistance of different polymers through the interaction of the wheels and weights. By selecting the appropriate wheels and weights, the test can be modified for various conditions. Standard methods for conducting this abrasion test include:

ISO 9352 – Plastics – Determination of resistance to wear by abrasive wheels

Sand/Rubber Wheel Abrasion Test:

This is a standardized method for evaluating the wear resistance of materials. A sample is pressed against a rotating rubber wheel while sand flows between them, measuring the volume loss over time. Relevant standards include:

ASTM G65 – Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus

Scratch Test:

The scratch test in wear testing evaluates a material's ability to resist wear caused by scratching or friction against other surfaces.

ASTM D7027-13 – Standard Test Method for Evaluation of Scratch Resistance of Polymeric Coatings and Plastics Using an Instrumented Scratch Machine. A linear scratch tester with a conical or spherical indenter is used to measure scratch resistance.

Factors Affecting Plastic Wear Resistance

Several factors influence the wear resistance of polymers, such as polymer structure, additives and environmental factors. Among them, additives have a significant impact on the wear resistance of polymers.

Here are some common additives:

Reinforcing Fillers and Fibers: Fillers like silica, alumina, and talc can improve wear resistance by providing a physical barrier to abrasive particles and strengthening the polymer matrix. Fibers and particles can enhance wear resistance by adding additional strength and rigidity.

Lubricants: Lubricants reduce friction between the polymer surface and abrasive particles, improving wear resistance.

Antioxidants: Antioxidants protect polymers from degradation caused by oxidation, which can reduce wear resistance.

UV Stabilizers: UV stabilizers protect polymers from degradation caused by ultraviolet radiation, which can also impact wear resistance.

The concentration or amount of additives can affect the degree to which wear resistance is improved. Processing conditions such as mixing, compounding, and molding also affect the dispersion and effectiveness of additives.

■ Introduction

Compliant with GB/T 1768 and ISO 7784-2 standards, BEVS 2816 AI Rotary Abraser is an instrument for determining the abrasion resistance of paints and varnishes, not only has the traditional functions, but also voice control and broadcast functions. It is widely used in wear resistance testing on leather, fillers, coatings, paper, floor tiles, plywood, glass, natural rubber, etc.

■ Features

► 4.3" Touchscreen, easy operation.

► AI Voice Control + Touch control

► Suitable for wear resistance testing of paints, varnishes, paper, plastics, textiles, etc.

► Compatible with various abrasive wheels and media to meet different testing requirements.

► Small footprint with smooth and quiet operation.

■ Technical Parameter

1. Specimen: Outer Φ100mm, Inner Φ8mm

2. Max specimen thickness: 12mm

3. Rotation speed: 1-99 rpm

4. Auxiliary weight: 250g, 500g, 750g

5. Marked weight: 500g, 750g, 1000g

6. Number of cycles: 1~9999