Pertenecer a la categoría: Seminar

Fecha de lanzamiento: 2024-12-24

Tarifa de clics: 5493

El editor: Ivy

Colección:

The wave of automation in coatings labs is sweeping the industry at an unprecedented rate, dramatically improving the efficiency and accuracy of experiments as well as significantly reducing costs.

So how does automation technology accomplish these goals? How will it change the future of coatings R&D? BEVS Intelligent Robotic Testing and Inspection System provides a perfect solution.

Intelligent Formula Preparation Station

Integrating intelligent testing/measuring instruments, robotic arms, mechanical movements and automatic control technology, This workstation not only fully automates the formulation preparation process, but also precisely measures and adjusts pH and viscosity levels and records all data throughout the preparation.

Reduces costs related to experimental materials, equipment maintenance, and labor, effectively controlling R&D expenses.

With AI and automation, formulations can be screened and optimized quickly, significantly shortening product development cycles.

Precise control of formulation ratios and process parameters ensures consistent and stable product quality.

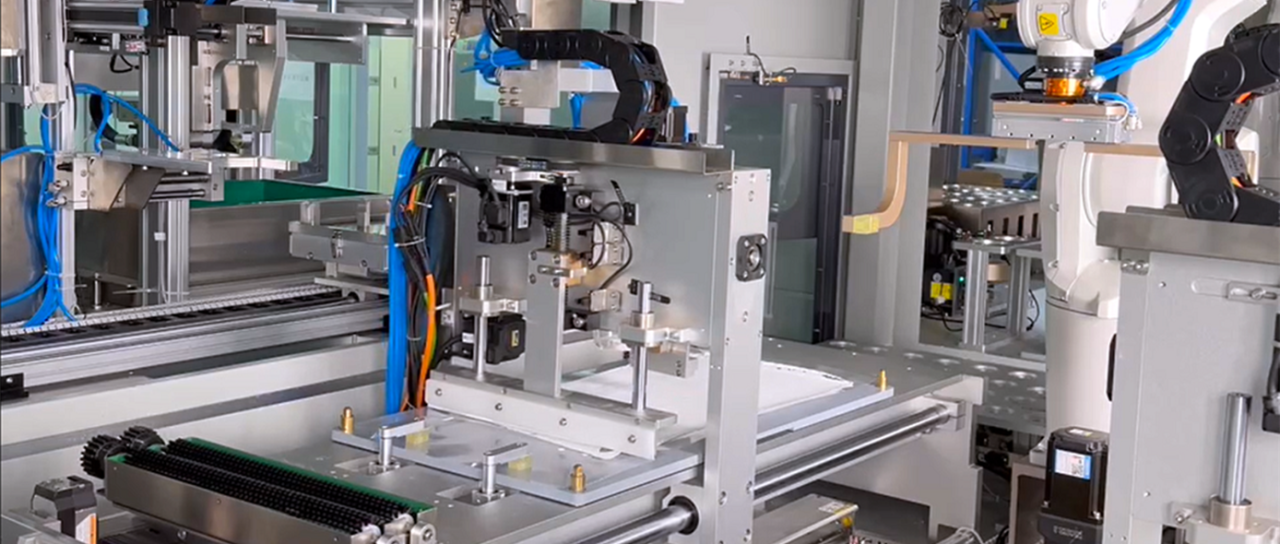

Intelligent Film Application Station

Can automatically complete multiple steps such as loading and unloading, coating and drying, which greatly improving reproducibility and efficiency in film applications.

Improve production efficiency

Automate multiple steps in the film making process, such as automatic sampling and coating, significantly increasing production efficiency and output.

Energy saving and environmental protection

Optimizes production processes and equipment operation to reduce energy consumption and material waste.

Capable of managing complex films requirements, such as multi-layer composite films and functionalized films, to meet market demand for high-performance films.

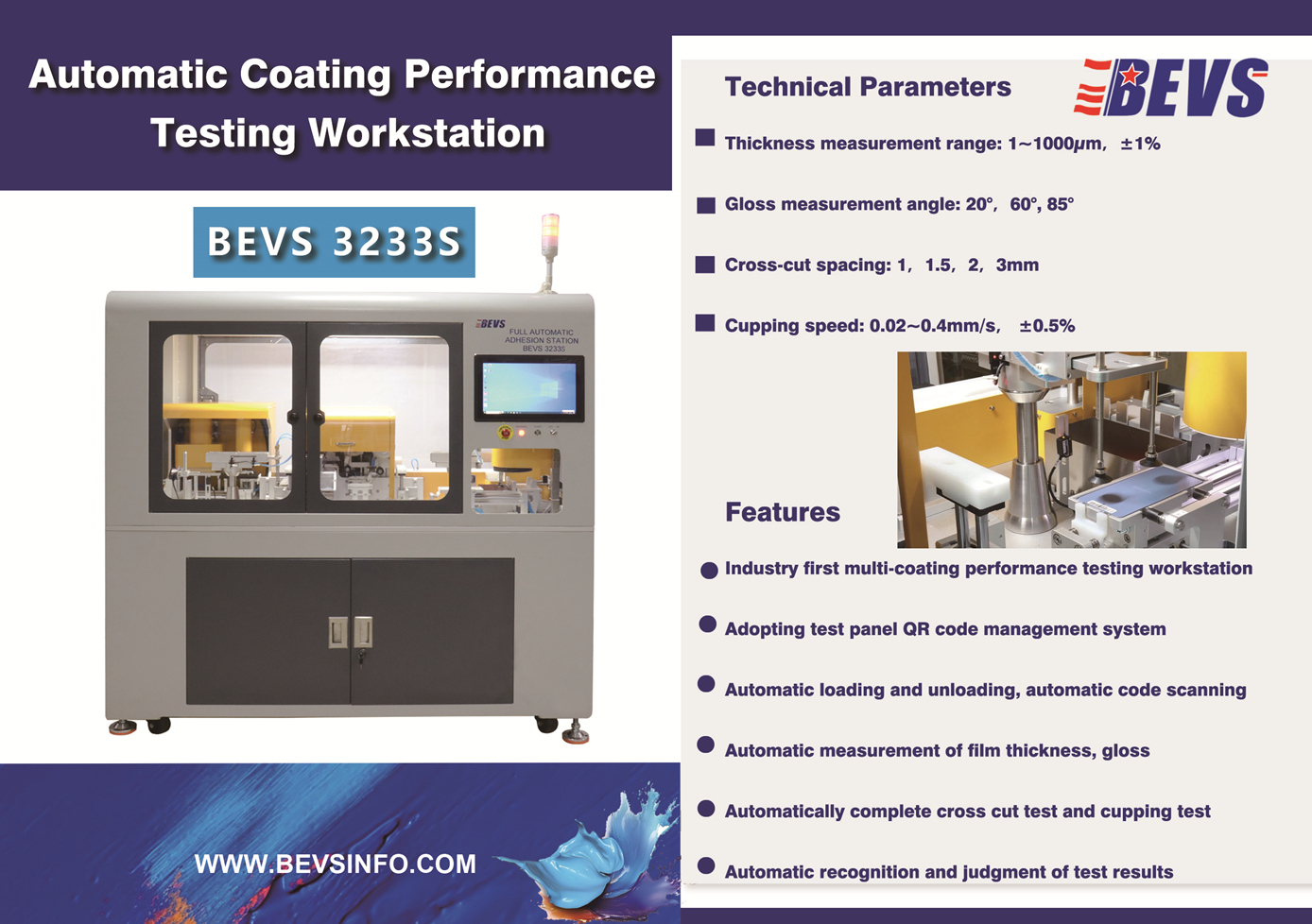

Intelligent Performance Testing Station

Equipped with advanced sensors and control systems, this workstation automates various coating performance tests, such as gloss, film thickness, color difference, contact angle, adhesion, cupping, etc., which can easily realize the whole process automation of coating performance testing.

Adopts QR code information technology to automatically manage samples, achieve automatic classification and storage. Visual recognition and automatic judgment of adhesion test results and cupping test results ensure the accuracy of each operation.

Data Collection and Analysis

Built-in data collection and analysis functions enable real-time monitoring of production status, collecting key data such as film making effect and equipment performance, and provide the basis for subsequent process optimization, fault prediction and maintenance decision.

While laboratory automation brings numerous advantages, there are also challenges such as high initial investment costs, technical complexity, the need for specialized technicians, and data security and privacy issues.

To address these issues, we have adopted the following strategies to provide better products and services to our customers:

Offering cost-effective automation solutions through technological innovation and product optimization.

Implementing user-friendly interfaces and tools, enabling easy operation for users without technical backgrounds.

Adopting advanced data encryption technology and security protocols to ensure the security and privacy of laboratory data.

The realization of full automation in coating laboratories will dramatically enhance experimental efficiency and accuracy, reduce costs, and free up researchers to focus on innovation and complex R&D tasks.

BEVS has already made remarkable progress in intelligent robotic automation testing and inspection systems. In the future, we will continue developing intelligent automation systems that incorporate advanced machine learning and AI technology, to achieve real-time data collection, analysis and processing, further improving testing efficiency and precision.