Produkt

- Dissolver

- Dichte / Kornfeinheit

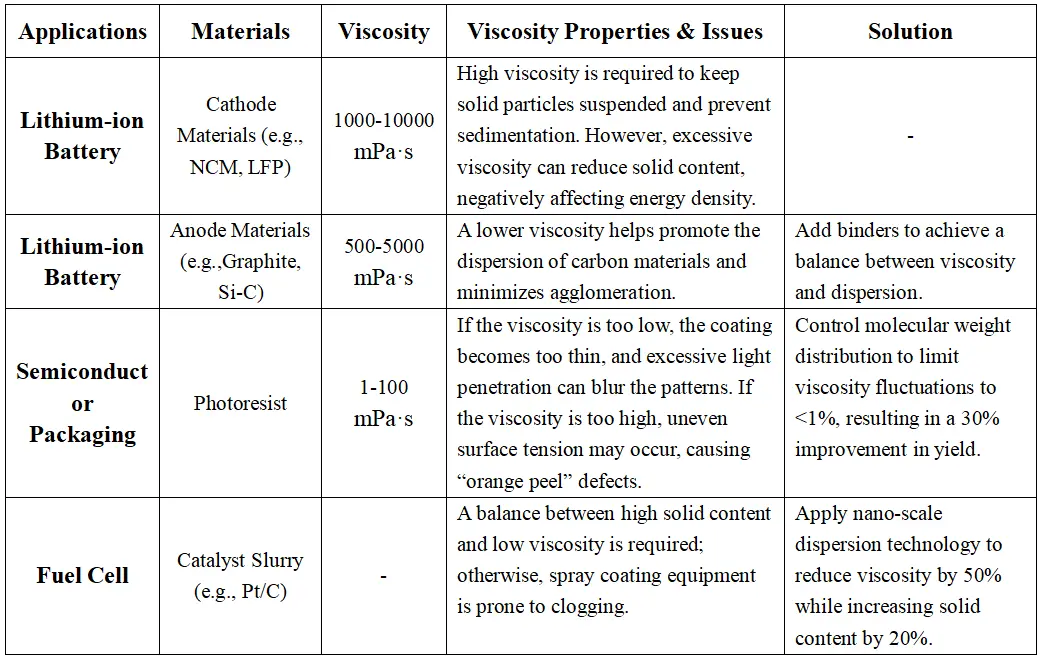

- Viskosität

- Intelligentes Kegel- und Platten Viskosimeter

- Intelligentes Rotationsverdünnungs Viskosimeter

- Krebs-Spindel-Viskosimeter

- Krebs-Spindel-Viskosimeter (manueller Typ)

- DIN Auslaufbecher mit Griff

- DIN Auslaufbecher

- ISO Auslaufbecher

- AFNOR Auslaufbecher

- Zahn Auslaufbecher

- FORD Auslaufbecher

- Iwata Auslaufbecher

- Cup Stand

- Film Applikation

- Automatisches Filmaufziehgerät kompakt

- Automatisches Filmaufziehgerät

- Spaltrakel

- Zweiseitiger Filmaufziehrahmen

- Lackhantel bzw. Vier-Schichtrakel

- Vierseitiger Applikator mit Reservoir

- Würfelförmiges Filmaufziehgerät

- Einstellbares Filmaufziehgerät

- Ablauf-Prüfrakel

- Verlauf-Prüfrakel

- Spiralrakel

- Halter mit Griff für Spiralrakel

- Prüfkarten

- Einstellbares Filmaufziehgerät (digital)

- Applikations Koffer

- Prüfblech Beschichtungsautomat

- Trockenzeit

- Schichtdicke

- Temperatur

- Farbe / Glanz

- Haftfestigkeit

- Härte

- Deformation

- Abrieb, Scheuer/Waschbeständigkeit