- وصف

- ورقة البيانات

- دليل الاستخدام

- البرمجيات

- فيديو

Introduction:

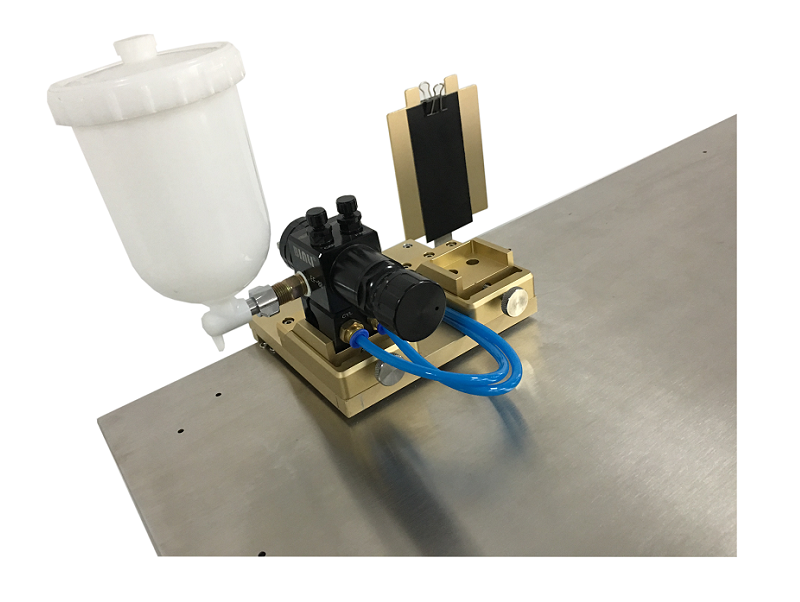

The BEVS 1828 Automatic Panel Sprayer is a fast, intelligent and automatic device for spraying panel, with advantage of reliable uniform coating for testing and evaluation. It is equipped with a 10-inch high-definition touch screen display for easy operation and has features like a one-button start, fully automatic spray, automatic cleaning spray gun, quick change of paint and spray gun. It is an advanced spraying equipment with intelligent programming spraying process, a good choice for spraying test panel in laboratory.

Features:

-With 10-inch high-definition touch screen

-Intelligent programming spray process

-Three-axis automatic spraying

-Optional single or dual spray gun

-Automatic control of spray pressure

-Quick replacement of the spray gun

Functions:

-Three-axis (X, Y, Z,) automatic control; X and Z axes are linked according to the setting program, and the Y-axis is automatically adjusted according to the distance parameter manually input or the preset in the mode (only for standard equipped spray gun)

-With cross wet spray process

-Multi-viscosity mode preset, input the required film thickness value and spray area, the system automatically calculates the spray cycles, the path and the start/end of the spray position, and spray the required thickness

-Custom spray mode: input parameters such as spray movement speed, gun distance, atomization pressure, spray cycles, start and end spray position, etc. It automatically sprays according to the set parameters. The custom mode parameters can be saved and applied next time

-The interface displays the current parameters in real time, such as the current coating thickness, the run spray cycles, remaining spray cycles, the estimated final film thickness, and the estimated remaining time

-Real-time monitor the environment, automatically power off to prevent explosion when reaching the set VOC (Optional function)

Technical Specification:

Spray Parameters:

-Panel moving speed: X-axis 50-300 mm/s; Y-axis 1-30 mm/s; Z-axis 50-300 mm/s

-Gun distance: 150-250 mm

-Atomization pressure: 0-0.7 Mpa

-Spray width (manual adjustment)

-Sample flow volume (manual adjustment)

-Spray gun nozzle diameter (optional according to actual conditions)

System Parameters:

-Applicable paint type: water-based or solvent-based

-Applicable paint viscosity range: 1-20000cps

-Moving speed: X-axis 50-300 mm/s; Y-axis 1-30 mm/s; Z-axis 50-300 mm/s

-Stroke length: 500 x 150 x 350 mm (X x Y x Z axis)

-Gun distance: 150-250 mm

-Atomization air pressure: 0-0.7 Mpa

-System pressure: 0-0.7 Mpa

-Panel lift height: 350 mm

-Spraying area: max 300 × 450 mm; or 9 pcs of 100 × 150 mm standard panels

-Spray gun type: gravity automatic spray gun

-Dimension (Lx W x H): 955 x 550 x 1200 mm (1700 mm extension rod)

Standard:

ASTM D823/A

Order Information:

BEVS 1828 Automatic Panel Sprayer (Including one automatic spray gun)

منتجات اخرى

-

التلقائي لوحة بخاخ

Introduction: The BEVS 1828 Automatic Panel Sprayer is a fast, intelligent and automatic device for spraying panel

颜色:

品牌:

型号:

尺寸:

قضيب رقمي قابل للتعديلIntroduction: The BEVS 1806F Adjustable Applicator is designed according to ASTM D823E. It consists of two precise

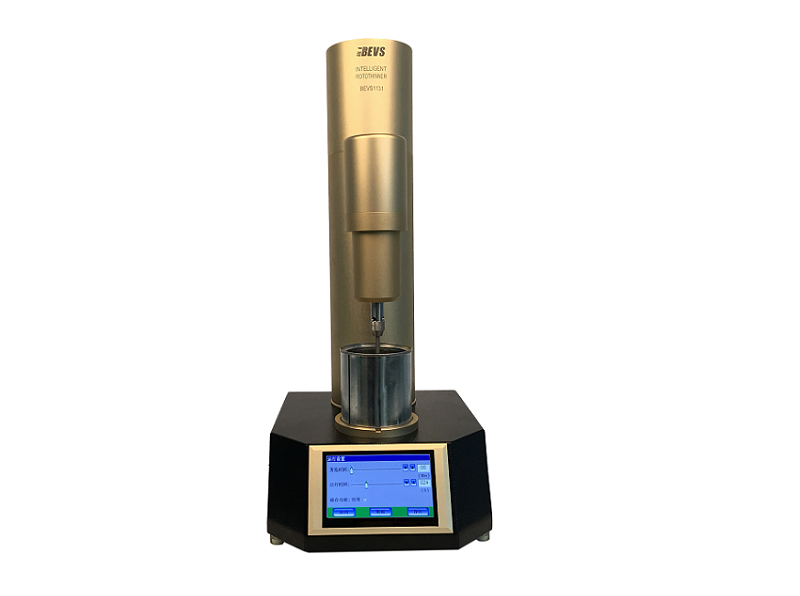

ذكي RotothinnerIntroduction: BEVS 1131 Intelligent Rotothinner is used to measure the viscosity of most non-Newtonian and Newton

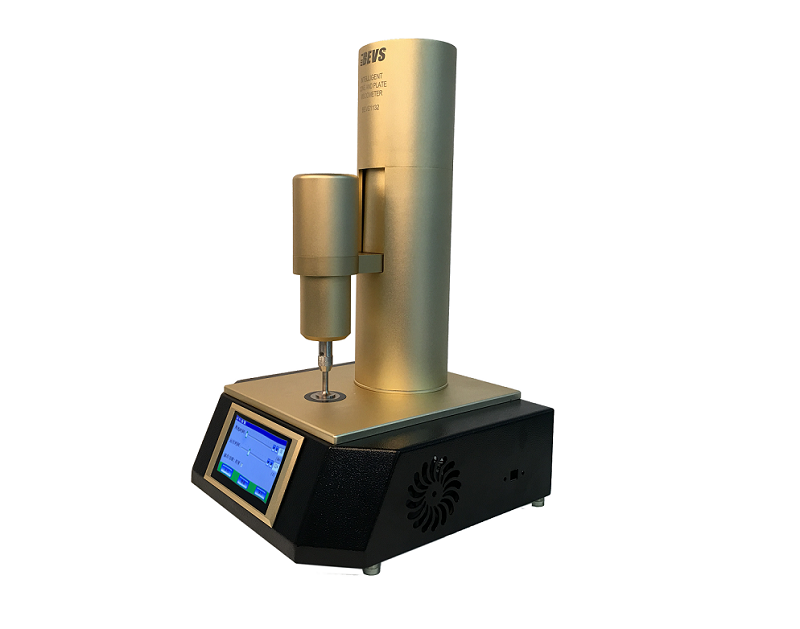

مخروط ذكي ولوحة قياس اللزوجةIntroduction: BEVS 1132 Intelligent Cone and Plate Viscometer is a highly accurate instrument that research the rh

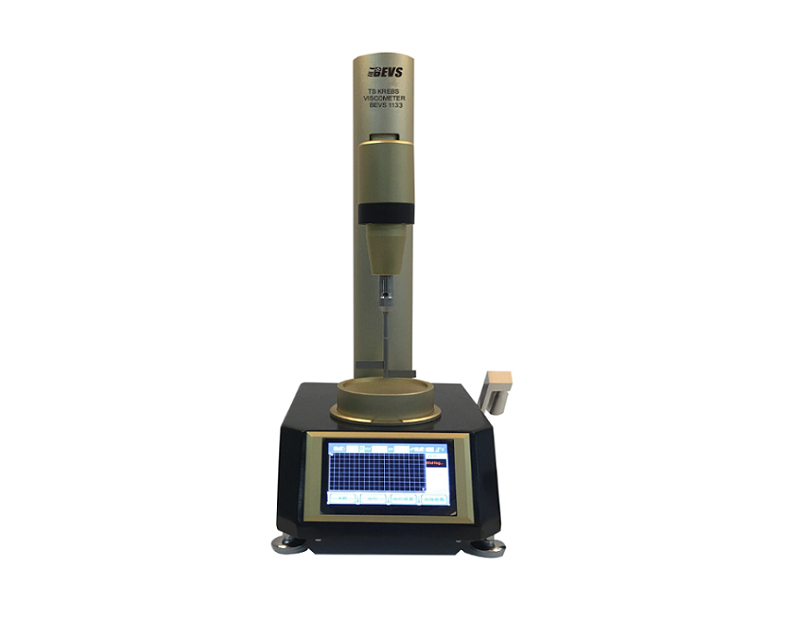

ذكي viscometer كريب (نوع اليدوي)Introduction: BEVS 1133 is a new manual type Intelligent Krebs Viscometer that adopting the new touchscreen techno

التلقائي فيلم قضيب المدمجةIntroduction: The BEVS 1818 Mini Automatic Film Applicator is an ideal machine for preparing a wide variety of pro

فرك تآكل فرك الرطبIntroduction: This machine is used to test the abrasion, scrub and washability performance for many kinds of mate

التلقائي الحجامة الفاحصIntroduction: BEVS Automatic Cupping Tester is an advance technology to efficiently assess the elasticity and cupp

ذكي اختبار صلابة البندولIntroduction: BEVS 1306 Intelligent Pendulum Hardness Tester consists of measuring the damping time of a pendulum

سحب التلقائي معطلة تستر التصاقIntroduction: BEVS 2201 Automatic Pull Off Adhesion Tester adopts the full touch screen technology, It enables to

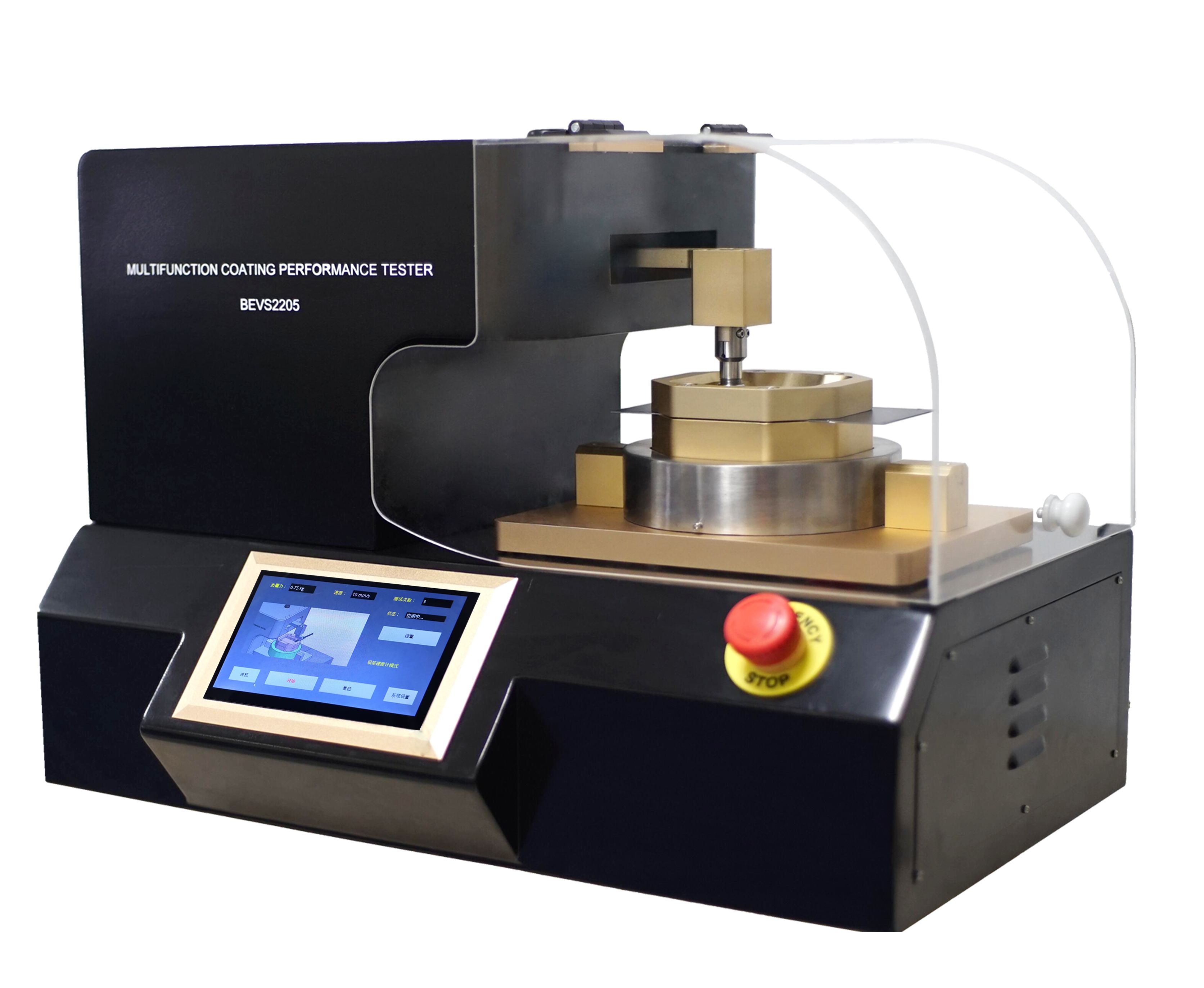

متعدد الوظائف طلاء الأداء تسترIntroduction: This instrument enables to test the scratch resistance performance, adhesion performance, hardness a

أربعة من جانب والقضيب مع خزانIntroduction: