Acceleration

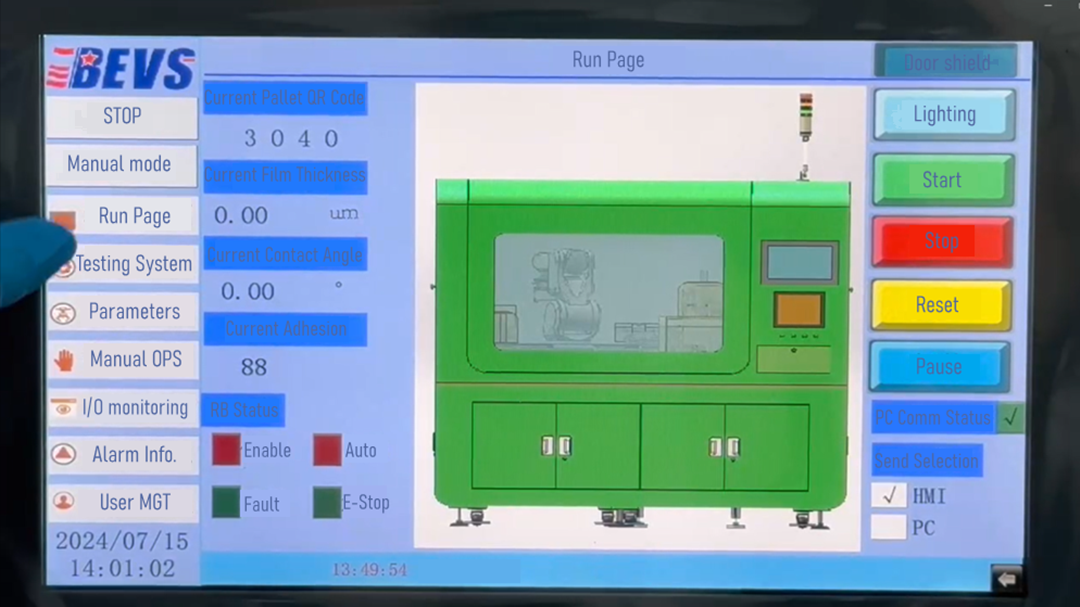

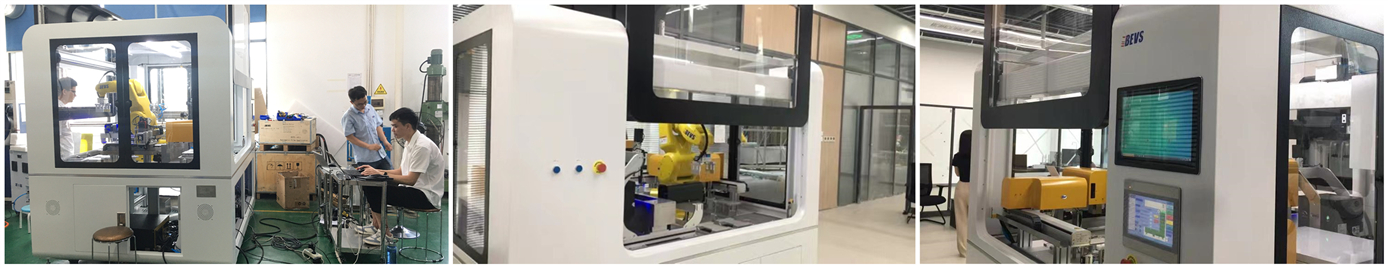

Recently, the installation of BEVS Full Automatic Coating Testing Station has entered the acceptance stage in a provincial materials laboratory. With the features of automation, high precision, multi-function, and data traceability, this equipment not only meets the customer's requirement for precise coating performance testing, running fast and changing samples quickly, but also can perform simultaneous operation of several modules.

Over the years, BEVS has been focusing on exploring the potential and demand in the field of automatic testing and devoting itself to the innovation and practice of intelligent robotic workstations. So far BEVS has launched intelligent workstations with independent intellectual property rights for different purposes, standardization, high compatibility and high reliability. BEVS also provides customized services for automatic workstations to meet the demand for precise testing in the industries of coatings, resins, rubber and plastics, etc.

Technological improvement

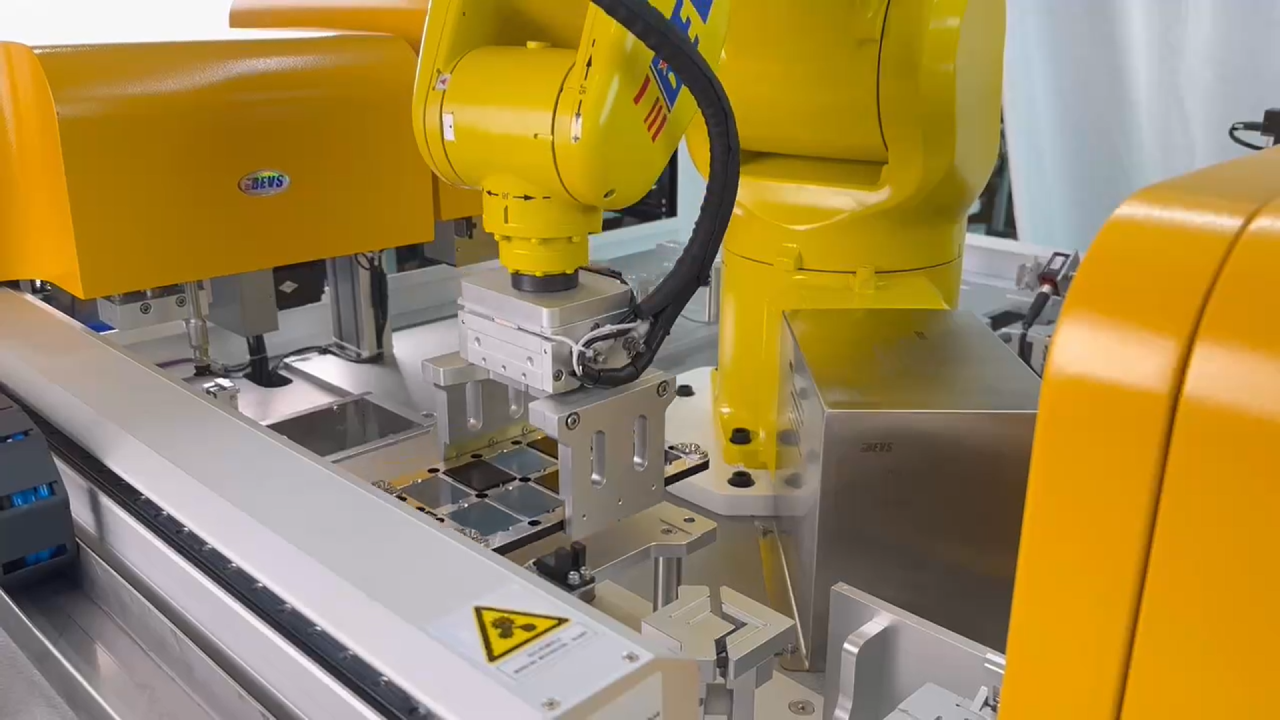

Automatic sample processing

Automatic scanning, loading, sorting, storage and other functions can be flexibly selected and matched according to the application scenarios.

Automatic film thickness measurement

Non-destructive testing technology is used to measure the thickness of dry film precisely and quickly, with the accuracy of 1μm.

Automatic contact angle measurement

With the full-automatic contact angle measurement technology developed by BEVS, precise liquid addition and accurate sample positioning are combined. Automatic loading and unloading, recognizing the height of the sample, liquid addition, liquid catching, and measurement ensure that accurate contact angle measurement data is obtained, with the accuracy of 0.1°.

Automatic adhesion measurement

With the high-precision pressure load control technology, motion control technology, and artificial intelligence visual inspection algorithm, it automatically completes the steps of scratching, removing debris, and sticking adhesive tape on the sample surface and grades the adhesion. The visual recognition accuracy reaches 0.02mm.

Better Performance

Automation

The whole process, from sample scanning, testing, sorting, storage and visual recognition, is automatically completed, with no manual operation. Equipped with our self-developed automatic measurement software, users can program automatic testing, greatly improving measurement efficiency.

High precision

Advanced measurement techniques and equipment are used to achieve micron-level precision of measurement.

Accuracy

Specialized research robotic arm makes sample loading, unloading and carrying accurately.

Multifunction

It is capable of testing a number of physical performance indicators of paints and coatings to meet the testing needs of different laboratories.

Data traceability

It can record the testing data of each test sample, realizing data traceability and quality control, which helps to find and solve problems in the production process in time.

Compared with similar products in Europe and the United States, BEVS intelligent workstation can be connected to front-end sampling workstation and supports remote programming and monitoring, which is more expandable. Mobility and connectivity are very friendly to installation and make it have various uses. Besides, they are more conducive to the stable operation and maintenance of the equipment.

BEVS intelligent workstation is compatible with third-party instruments, plug and play, which enables faster and more convenient deployment, saving enterprise operating costs dramatically.

BEVS intelligent workstations can be widely used in product development and quality control in the fields of coatings, new energy batteries, inks, packaging, printing, household chemicals and automobiles, etc. In addition to developing and manufacturing state-of-art products, BEVS also has the ability to provide stable products supply, which guarantees rapid implementation of customer’s projects.