In the field of material science, coating hardness is one of the key indicators for assessing product quality. Coatings not only need to provide an attractive appearance, but more importantly, they must protect the substrate and enhance properties such as wear and corrosion resistance. The automatic scratch tester, as an efficient testing instrument, can accurately assess the hardness and abrasion resistance of coatings on different materials.

Working Principle

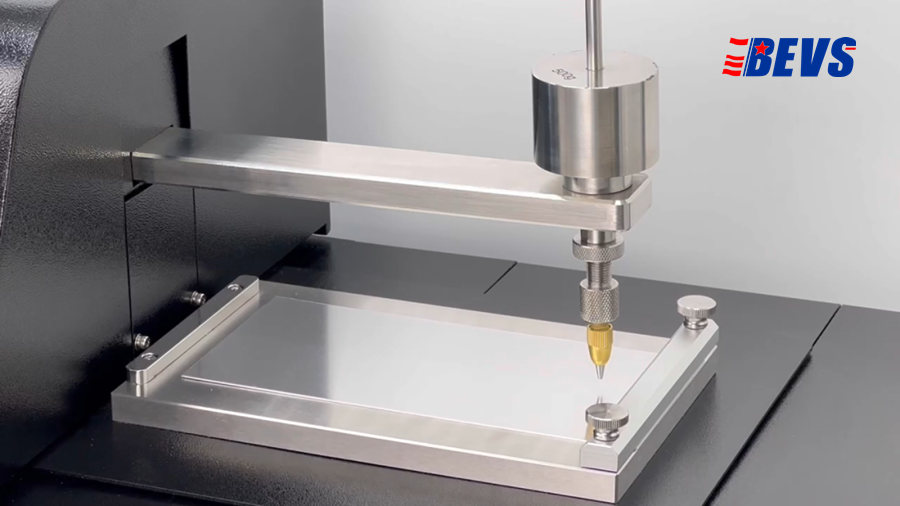

The automatic scratch tester operates by applying a gradually increasing load on a high hardness stylus, until the coating is scratched. The load applied when the coating is scratched, known as the critical load, is used as a measure of the coating's hardness.

Technical Features

Constant Stylus Movement Speed. Ensures consistent stylus movement speed under different test loads, improving test accuracy.

Precise Load Control. Ensure good repeatability of the pressure applied to the tip of the stylus through precise torque control.

Automated Testing Process. Automatically completes the scratching process, reduces human error and improves testing efficiency.

Multiple methods of judgement

1. Weak Current Test Tech. When the coating is scratched, the weak current forms a circuit through the scratching needle, substrate and base, recording the test results and critical load.

2. Acoustic Emission Mode. When the coating is scratched, an acoustic signal is emitted, recording the test results and critical load.

Application Cases

In the automotive industry, many components require coatings of certain thickness and strength to enhance surface performance, the testing of coating hardness is an important part of the manufacturing process.

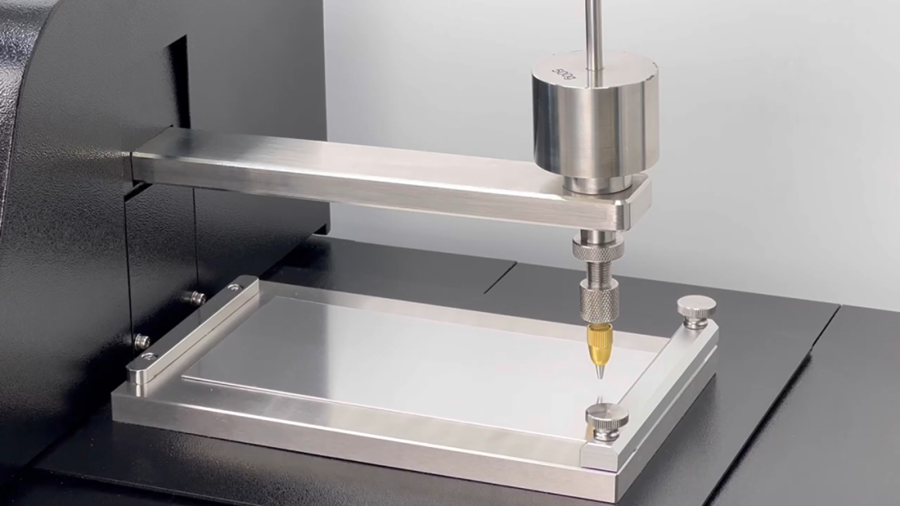

We take the BEVS 2801H Automatic Scratch Tester as an example to introduce the testing process of the adhesion of hard coating on aluminum alloy substrates. Through precise scratch testing, the critical load of the coating is determined and the hardness of the coating is assessed. Following are the test steps:

01

Test Preparation

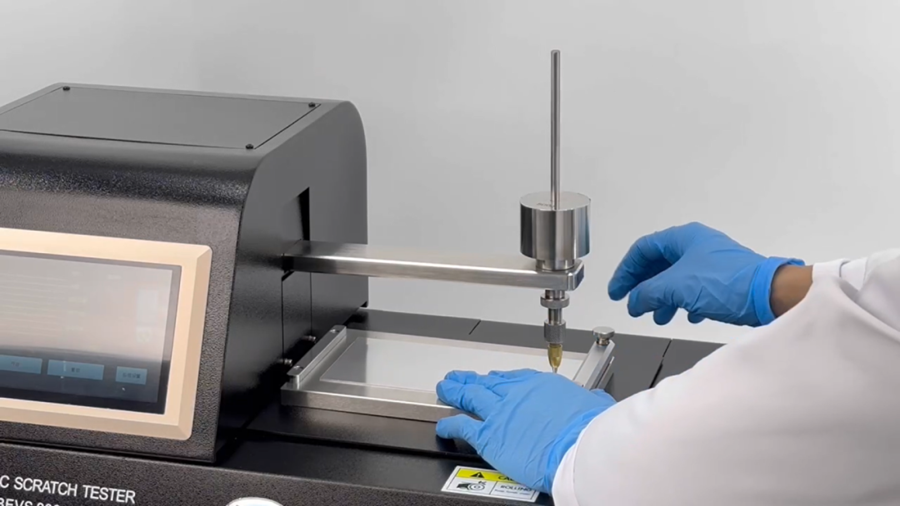

- Ensure the test sample's surface is clean and oil-free, and securely fixed on the test platform of the Auto Scratch Tester.

02

Equipment Setup

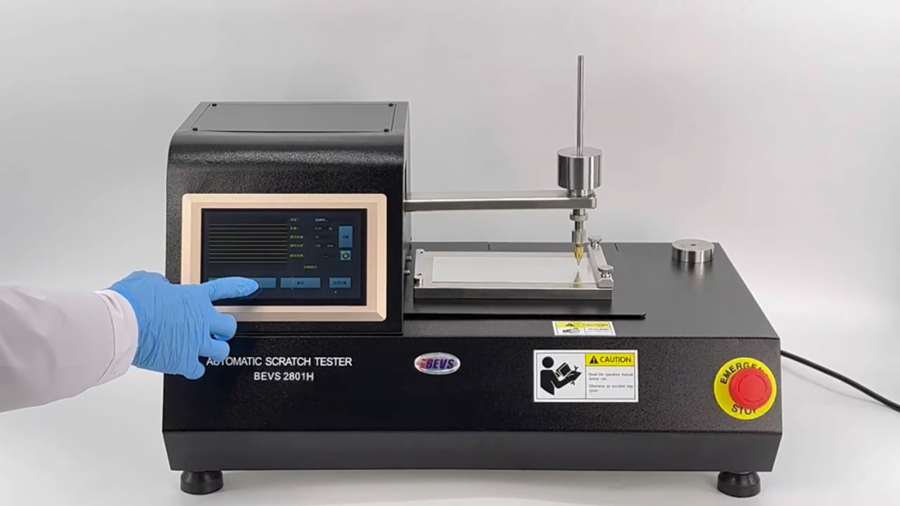

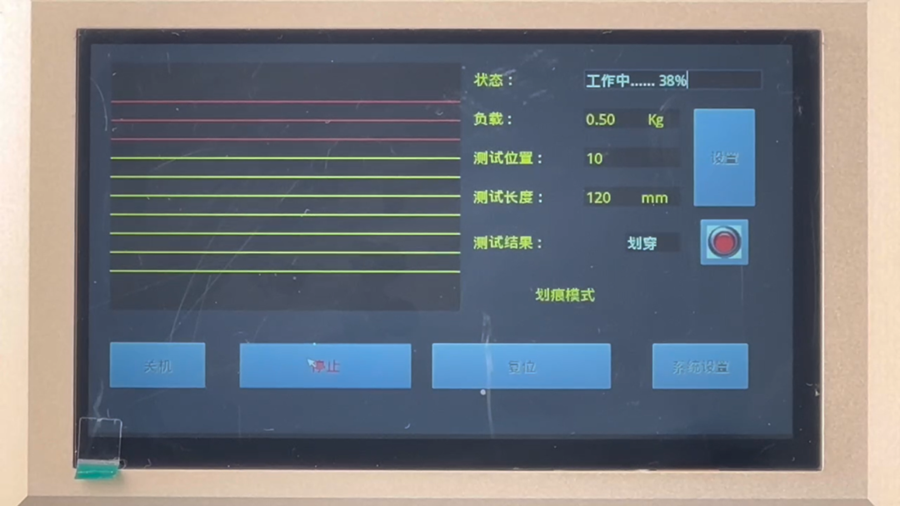

- Set appropriate test parameters based on the coating characteristics, including scratch speed and scratch length.

For instance, the BEVS 2801H provides a scratch speed range of 2 to 50 mm/s and can manually load weights up to 2 kg. With the settings, it can perform 1 or up to 17 tests.

03

Judgement Methods

- The Automatic Scratch Tester provides two judgement methods including weak current test technology and acoustic emission mode at the same time, to help experimenters quickly and accurately judge the test results.

04

Testing Process

- Activate the automatic scratch tester. The high-hardness stylus scratches on the coating surface until the coating is scratched. During the process, the sensor monitor weak current generation, emit a buzzing sound, and directly display the result on the screen.

05

Result Evaluation

- Analyze the load values and scratch result to assess the coating's adhesion. If the adhesion does not meet standards or expectations, adjustments to the coating formula or process may be needed.

06

Repeat Testing

- To ensure the accuracy and repeatability of the results, should conduct multiple tests, and the average value should be taken for the final assess result.

Beyond automotive, the Automatic Scratch Tester can also be widely used in adhesion testing of other coatings, such as aerospace, architectural decoration, and furniture manufacturing and other fields.

As a high-precision testing instrument, the Automatic Scratch Tester provides a standardized and automated solution for assessing coating adhesion. With the continuous advancement in material science, the Automatic Scratch Tester will play an important role in more fields, becoming a reliable assistant in material quality control.