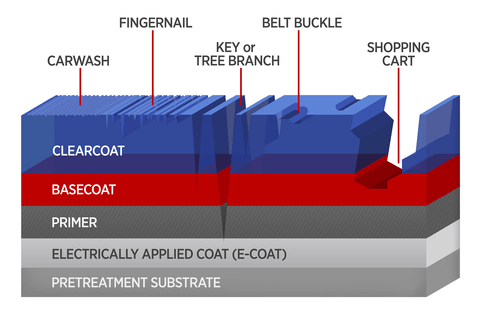

In the industrial field, coatings are commonly used to protect metal products, reduce friction, and improve wear resistance. For example, tool blades are often coated with a layer of tool coating to increase their lifespan and cutting efficiency. In the field of architecture, coatings are used for exterior wall insulation, waterproofing, decoration, etc. In the automotive industry, coatings are used for body rust prevention, improving appearance texture, and reducing wind resistance. In the aerospace field, coatings are used to improve the corrosion resistance of aircraft surfaces, reduce frictional resistance, and reduce radar reflection.

△

Automotive composite body coatings

BEVS 2811

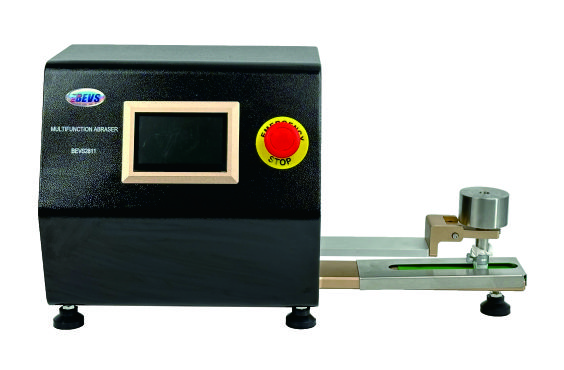

Whether for aesthetic or functional reasons, premature surface damage to coatings can lower consumer perception of product quality. The BEVS Multifunction Abraser is suitable for testing the scratch resistance of coated materials, non coated materials, and other composite materials. It can also be specifically used for color fastness testing of decorative fabrics, automotive interiors, velvet fabrics, inks, such as textile carpets/leather/synthetic fiber blended fabrics, and embossed decorative printing and brushing products.

BEVS Wear-resistant/Color Fastness Solution

In practical use, coatings may be affected by various adverse factors such as friction, scraping, and wear, among which scrath is a common form of damage.

The BEVS Multifunction Abraser has a stable overall structure and adopts a precise electronic control system. By precisely controlling the running speed and testing load of the workpiece, it simulates the influence of various factors on the coating to test the hardness and wear resistance of the coating surface, thereby evaluating the durability and service life of the coating in actual use.。

It is also possible to test the friction color fastness of different materials, evaluate the feasibility and advantages of new materials, and provide a basis for material improvement and innovation.

Why has BEVS 2811 become a master in this industry?

• Easy to operate: Designed with a touch screen, intuitive and convenient

• Flexibility: Adjustable running stroke, adjustable running speed, and replaceable friction pressure

• Multi function: Capable of replacing fixture heads and sample platform compatibility with different standards for testing

• Reliability: Adopting advanced techniques to ensure the reliability and accuracy of test results

Technical parameter

Stroke: 20~155 ± 5mm

Running speed: 0~70 ± 1spm

Pressure: 9 ± 0.2N

The application field continues to expand

Widely applied in fields such as architecture, automotive, aviation, and electronics in recent years.

Standard

GB/T3920, AATCC8, AATCC165, ISO105-X12

GB/T1770, GB/T7706, GB/T23989