The coatings of automotive coatings can generally be divided into three categories, namely primers, middle coats and top paints. The primer is electrophoretic paint, which can play the role of anti-corrosion, anti-rust, anti-strike and anti-aging. The role of the middle coat is UV resistance, stone chip resistance and the base of the color paint. As the coat of a car, top paint is one of the important reference conditions for customers to choose a car. The main functions are as follows:

① Protective effect: As an outdoor vehicle, automobiles are eroded by moisture, oxygen, industrial atmosphere, carbon dioxide and other media in the atmosphere for a long time. The car paint forms a firmly attached continuous film layer on the car, which can avoid the chemical or electrochemical reaction between its surface and the surrounding medium, and prevent or delay the occurrence and development of car damage.

② Decorative effect: The surface of the car is painted with various brightly colored paints, which looks elegant, bright and comfortable, and shows the personality of the vehicle. The plump paint film can also improve the grade of the car.

③ Marking function: The color of the car paint can mark the type and function of the car, such as green for postal cars, white for ambulances, red for fire trucks, etc.

④ Other functions: Some automotive coatings can improve the comfort and sealing of the car and prevent noise caused by vibration.

Commonly used testing standards for automotive coating include paint performance testing, construction performance testing, and paint film performance testing. Thickness tester detects coating film thickness in dry film state, etc. Relevant standards involve methods such as: paint film impact resistance measurement method, paint film gasoline resistance measurement method, paint film thickness measurement method, paint film weather resistance rating method, paint film weather resistance measurement method, etc.

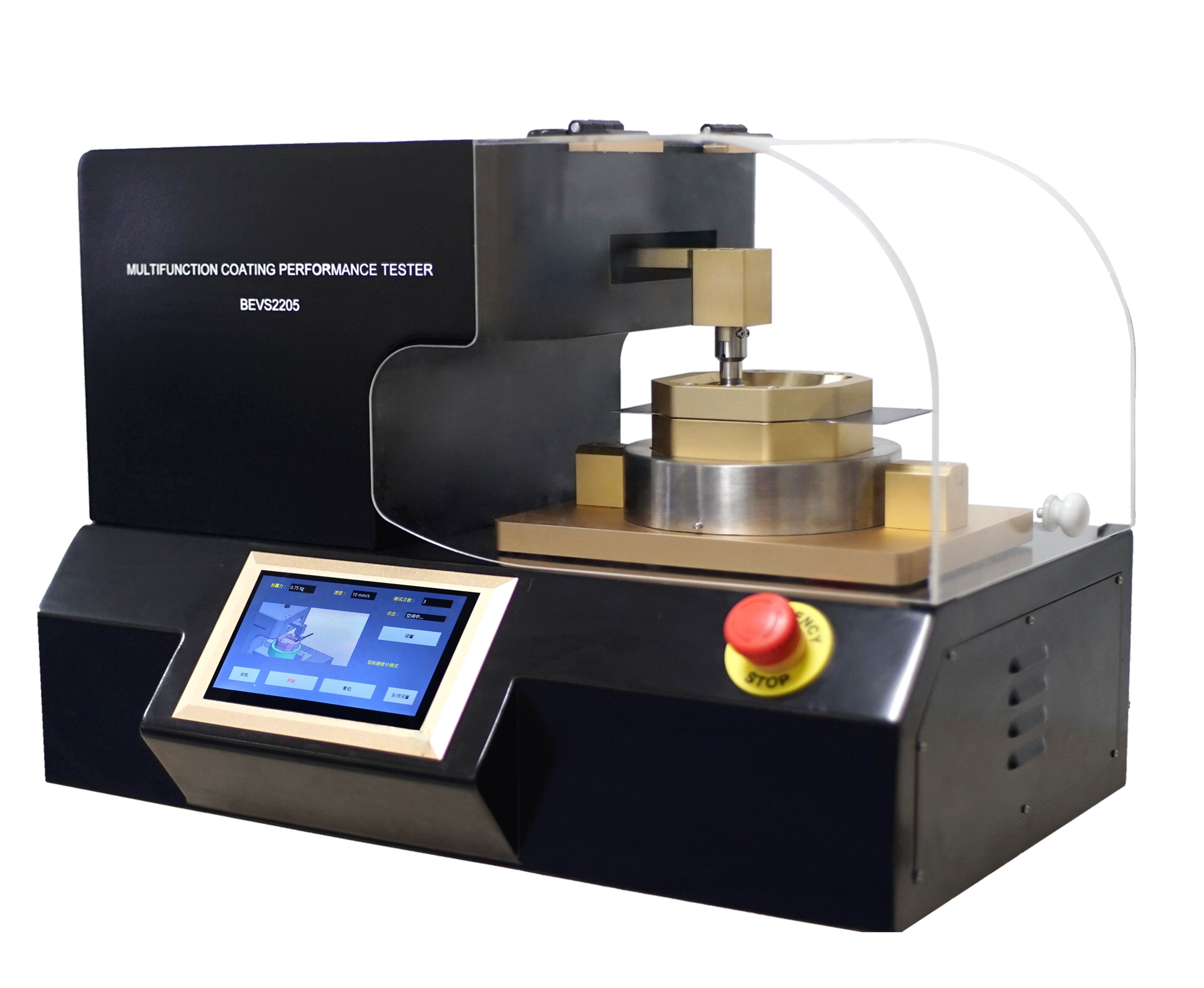

Independent research and development, integrating 4 functions of cross-cut, scratch, pencil hardness and wear resistance

Fully automatic operation, greatly avoiding errors caused by human operation

Color touch screen for easy operation

One machine with multiple functions: cross-cut mode, pencil hardness mode, scratch mode and rotary abrasion tester mode.

The test platform automatically locks the sample, rotates and moves automatically

Data storage and report output.

02

ISO 2409-1992,ASTM D3359,BS 3900 E6,GB/T9286-98,ASTM D3363,ISO15184

Especially suitable for the development and application of automotive coatings

A must-have instrument for measuring hardness for colleges, scientific research, and QC personnel

Invention patent number: ZL201810868615.4

Color touch screen, fully automatic operation

Automatic recognition of the pendulum rod, automatic recognition of the level

The test platform automatically locks the sample, automatically rotates and moves the temperature and humidity environment monitoring

Vibration warning

02

ISO 1522,ASTM D4366, NF T30-016, BS 3900 E5, DIN 53157

Built-in operating system, real-time monitoring

Invention patent number: ZL201510192397.3

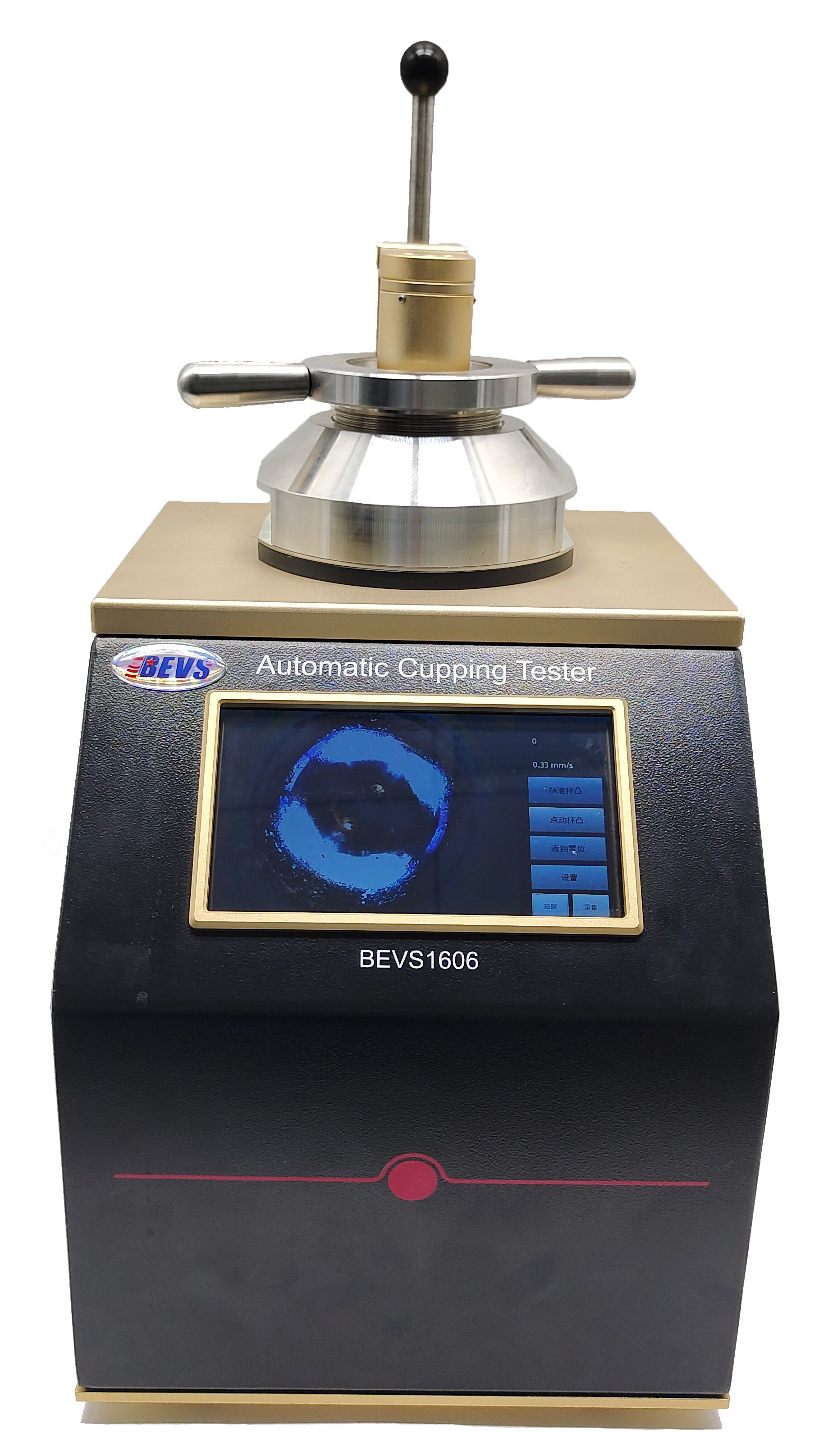

Touch screen man-machine interface

Real-time display of cupping process, cupping depth and speed

Self-contained photo and video function

Automatic zero calibration

02

ISO 1520,GB/T9753, DIN53166

With the support of many direct users and global agents, the BEVS brand has been widely used in related industries and continues to play an important role in value-added services for users.

BEVS makes your inspection work save time, without trouble and worry!